- 4 Minute Fills

- Spray More, Fill Less

- 4 Product Separation

- Many Configuration Options Available

Dash Models

See It In Action

Explore Key Features

Download

Unique Features of the Dash

Concept

Developed to accomplish two primary objectives,

1. Reduce fill times to keep the sprayer spraying.

2. Keep chemicals separated to guarantee chemical efficacy.

The Dash automates chemical mixing and cleaning, reducing the possibility for human error, decreasing the time needed to fill a sprayer, and increasing over all sprayer productivity.

Design

fill process

Based on our testing and customer feedback, the process of loading 4 different chemicals into a 1,200 gallon sprayer will take less than 4 minutes.

Explore Features of the Dash Trailer

Hover and Click for Interactive Display and Video

Available Options

Tanks

Includes hoops for mounting and internal baffles.

| Capacity | W” x L” x H” |

| 3,250 gal | 88 x 146 x 79 |

| 3,750 gal | 88 x 146 x 91 |

| 4,250 gal | 88 x 146 x 101 |

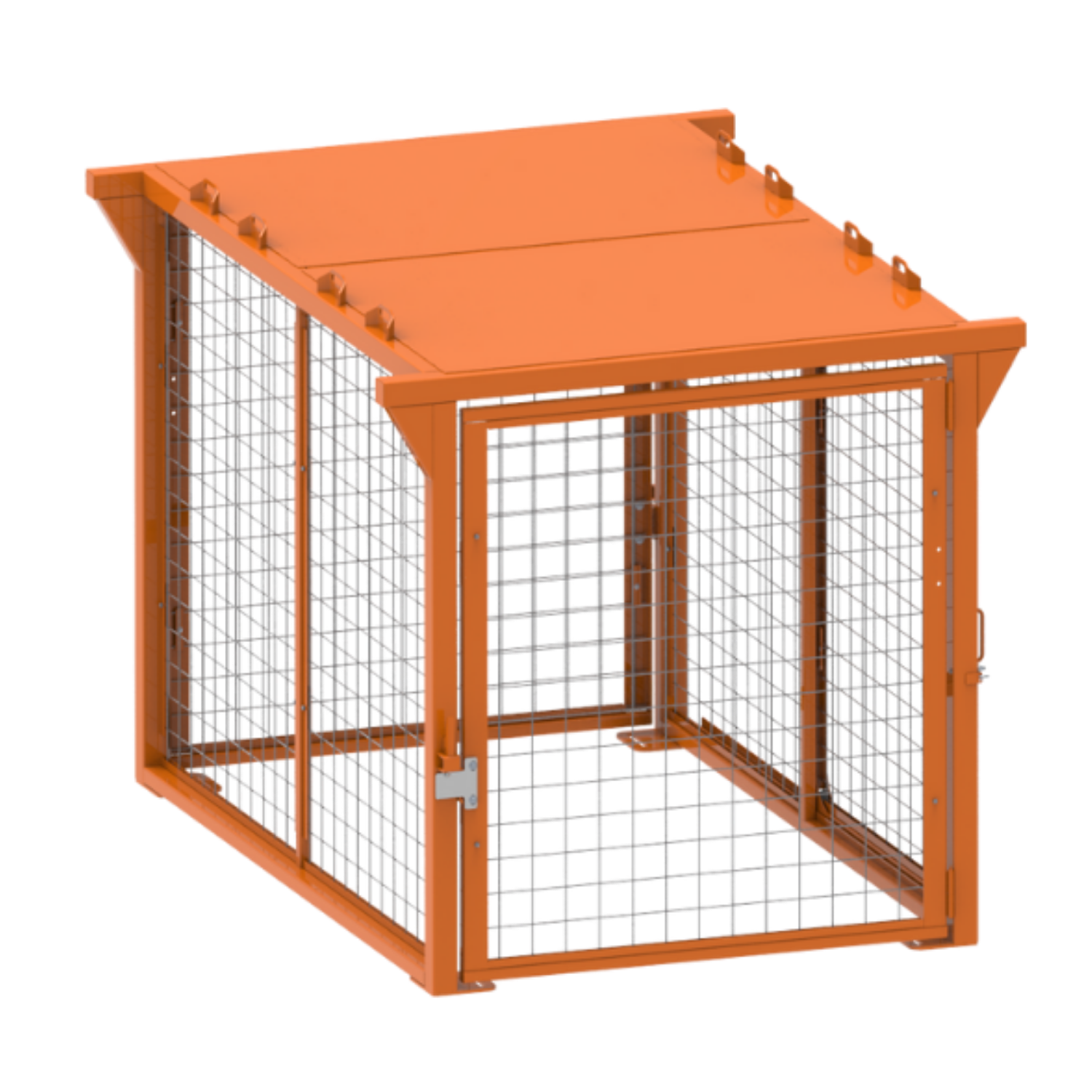

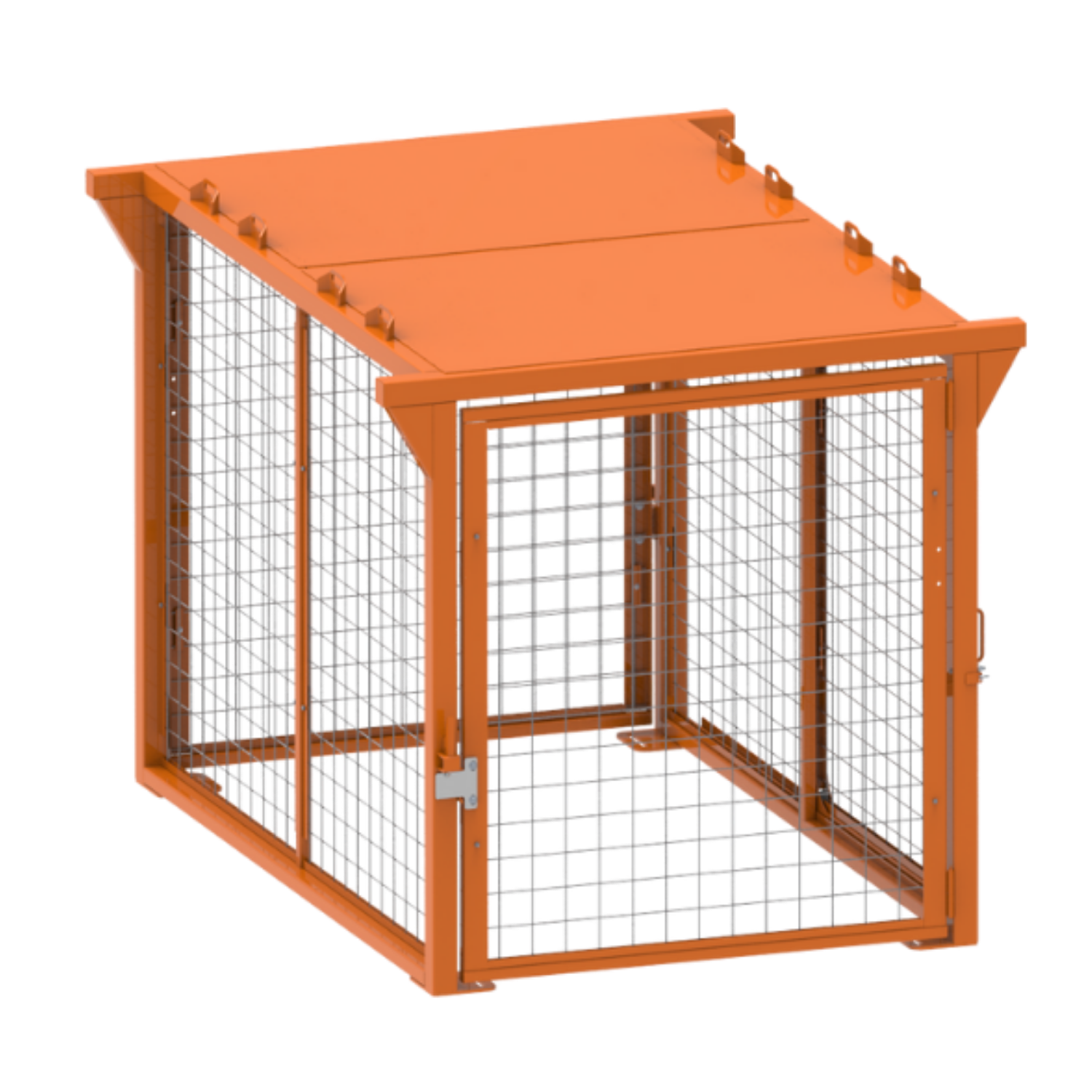

Cage with tote platform

Keep pallets of boxes contained while transporting. Load from either end or access from side door. Store totes above on tote platform. Available in 5’ or 6’ high configurations.

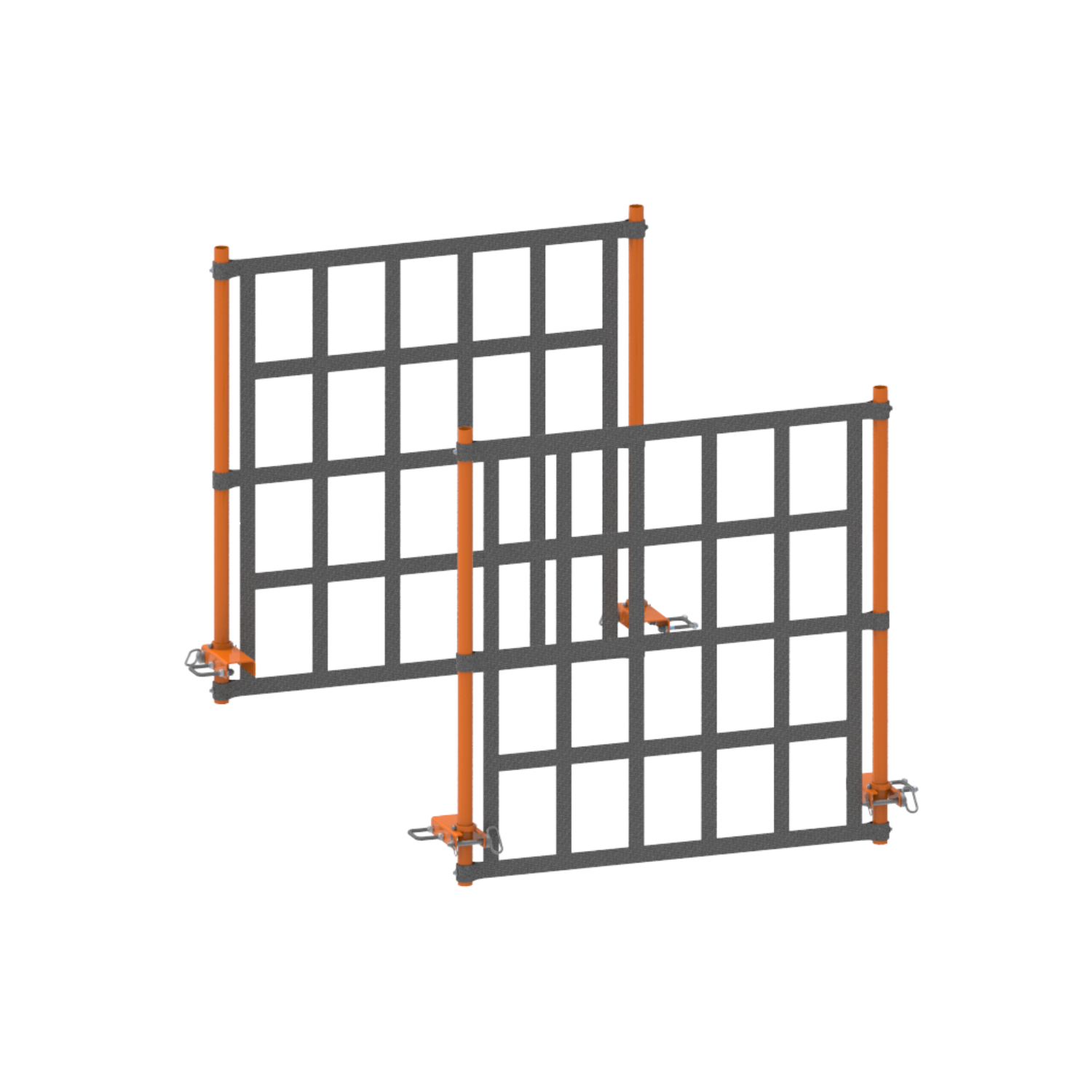

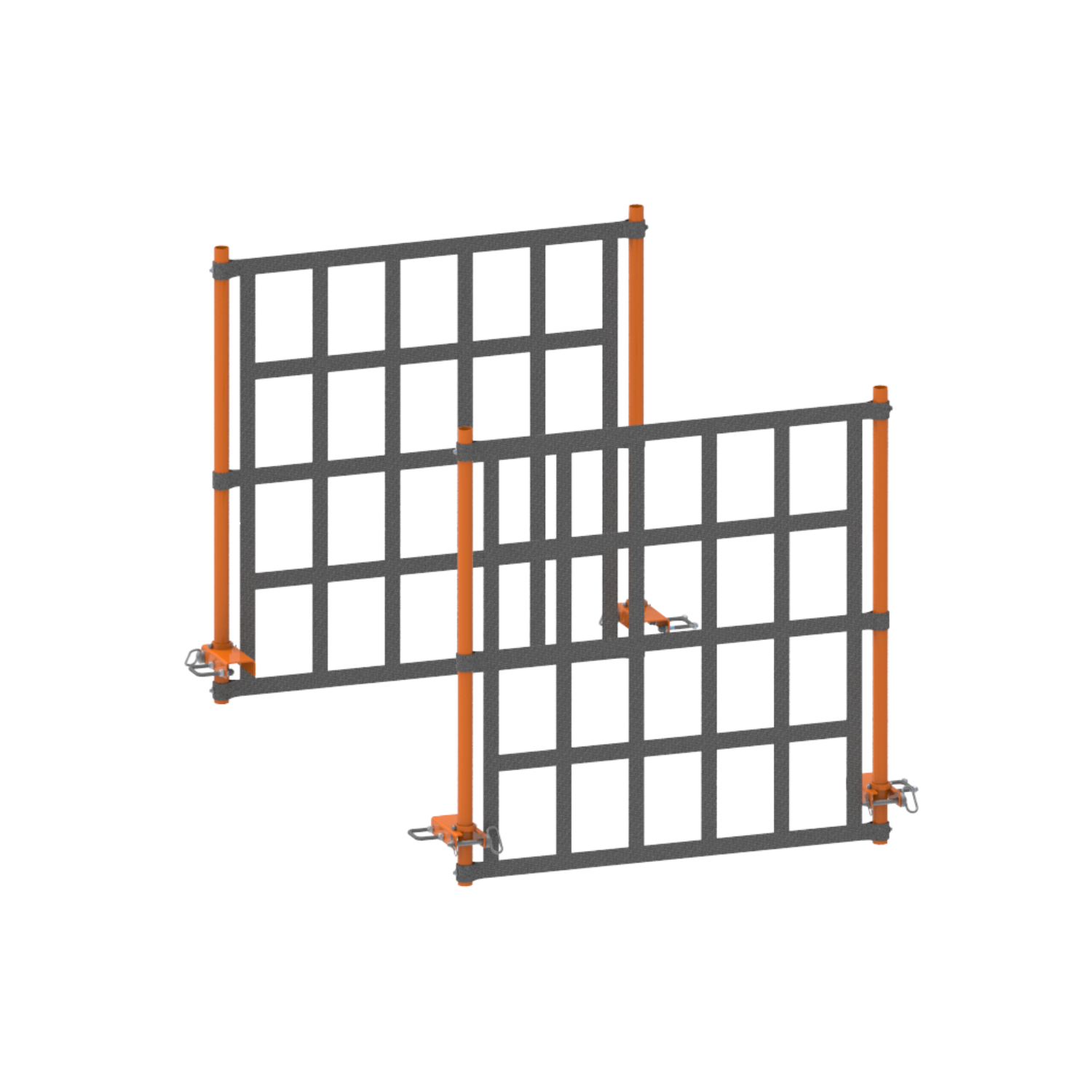

tote platform

IDesigned to mount to the Dash to store totes above inductor tanks and use gravity to fill. No transfer pumps needed, gravity always works on earth. Frees up deck space..

cargo net

tote rinse kit

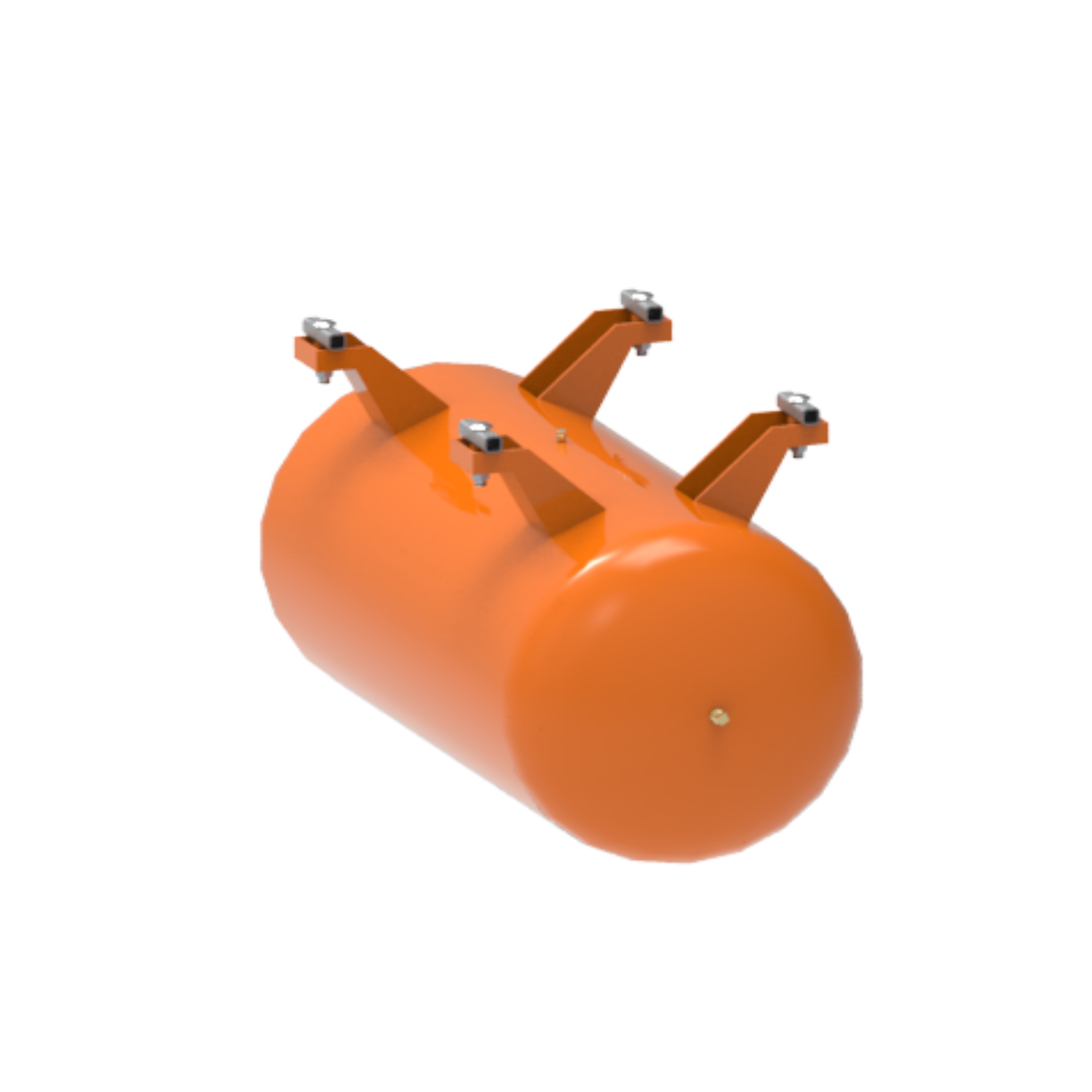

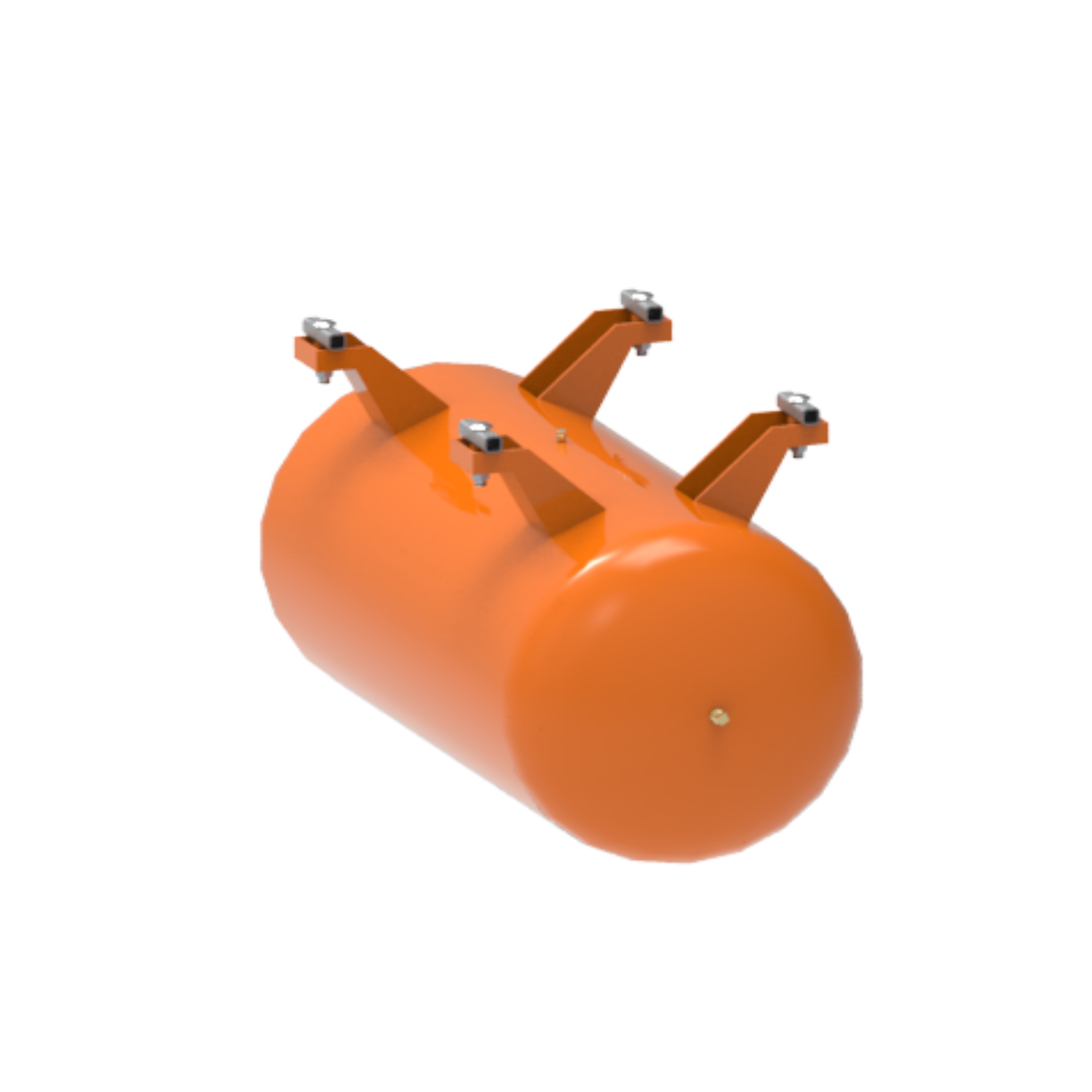

60 gal air stronage kit

An additional air tank can be added. This tank has a valve that allows the truck to air up first, before storing an additional 60 gallons of air.

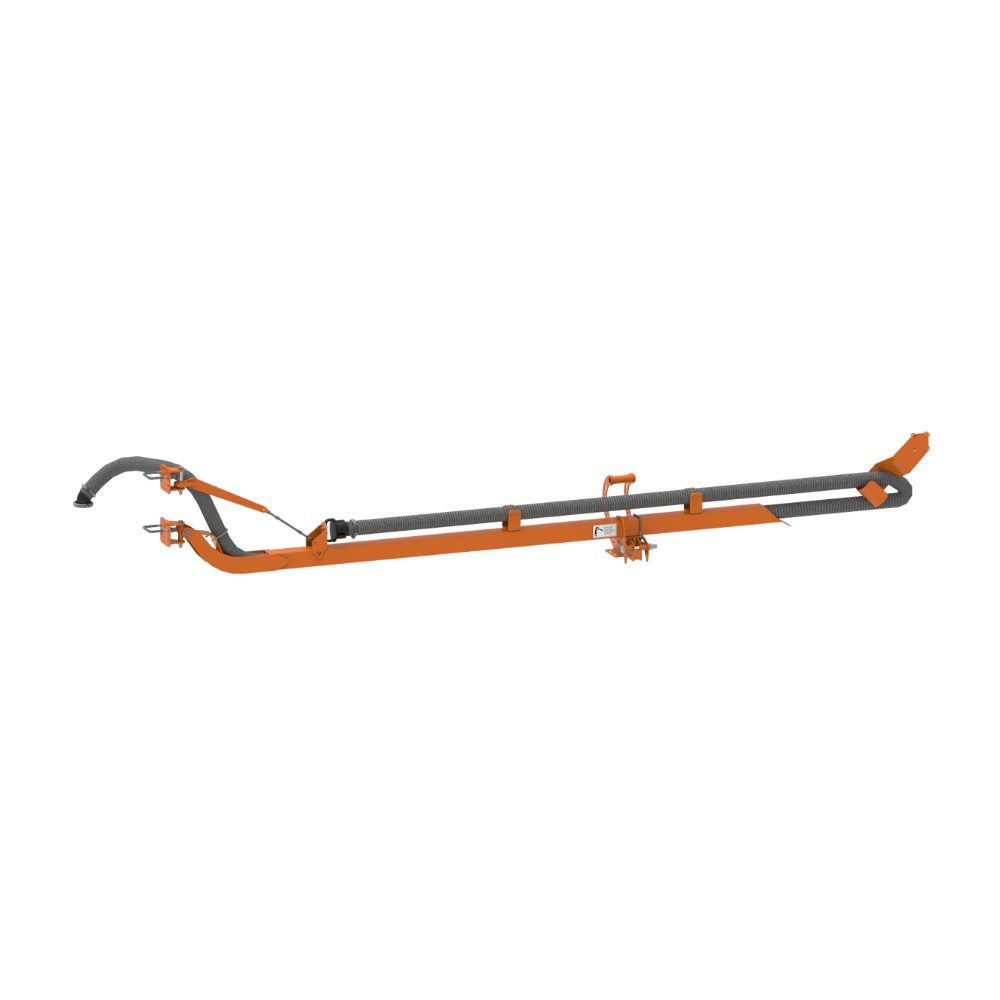

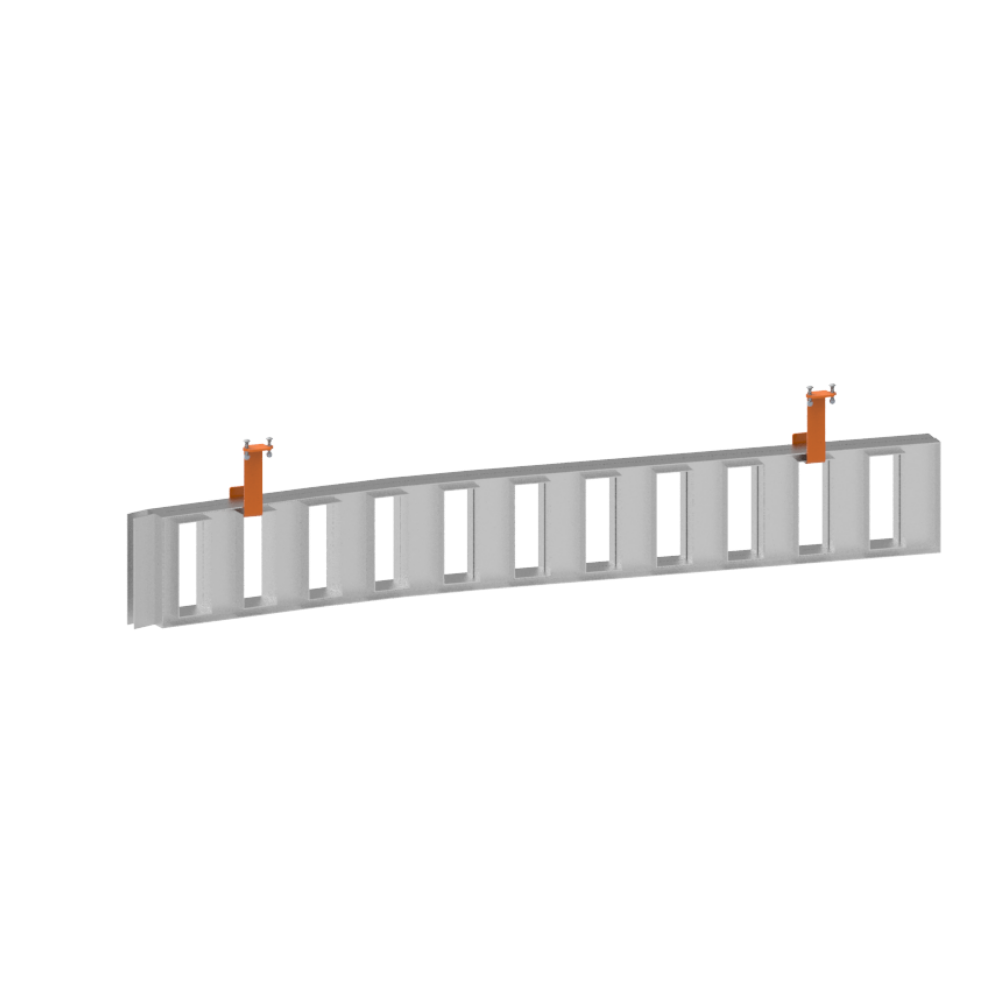

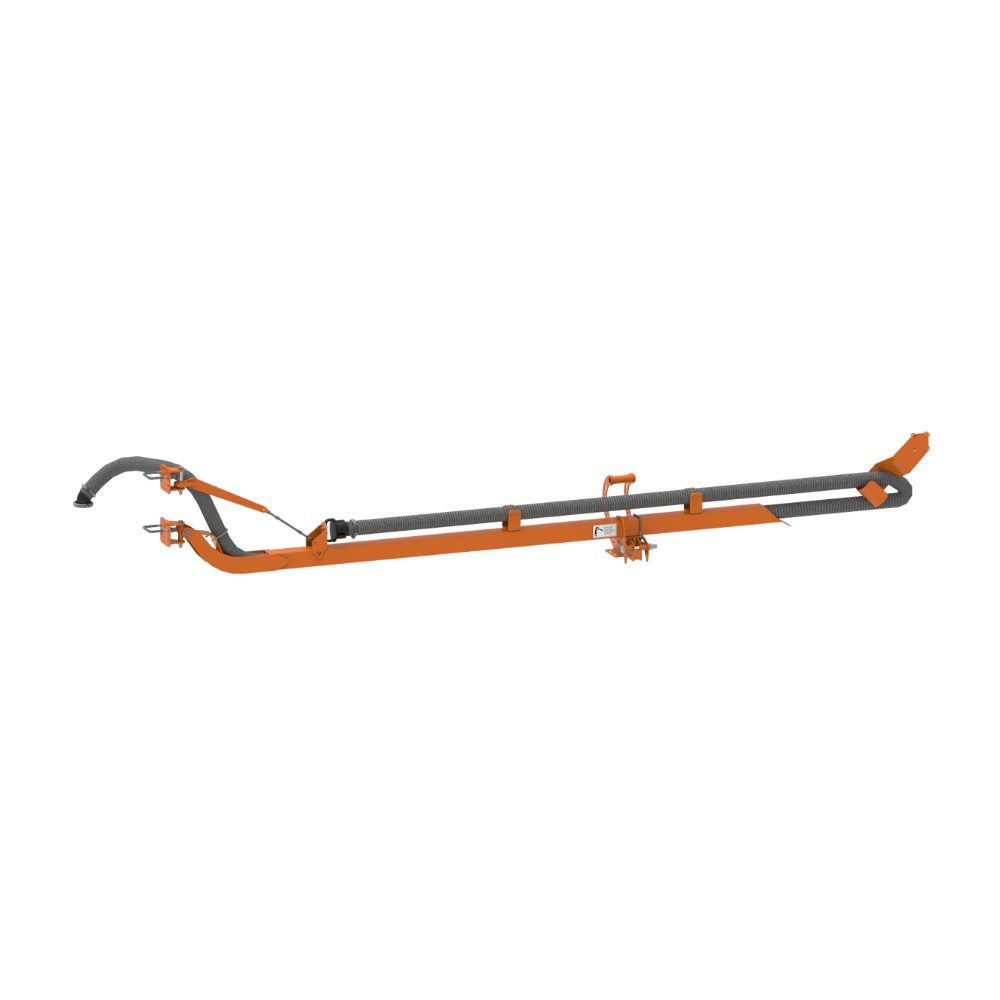

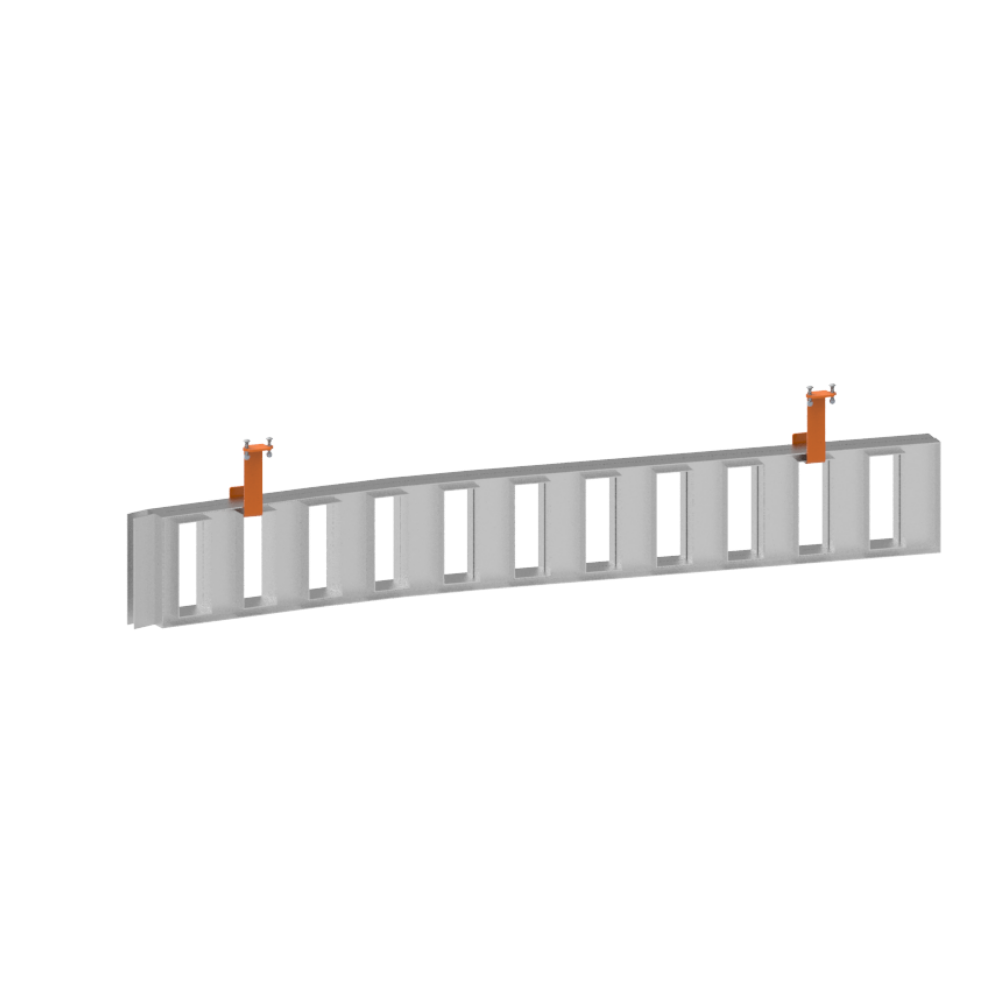

boom kit

INo more lugging heavy hose. Mounts to Dash and has approximately 28’ of total extension. Includes boom cradle and quick release handle. Premium Hose Kit available.

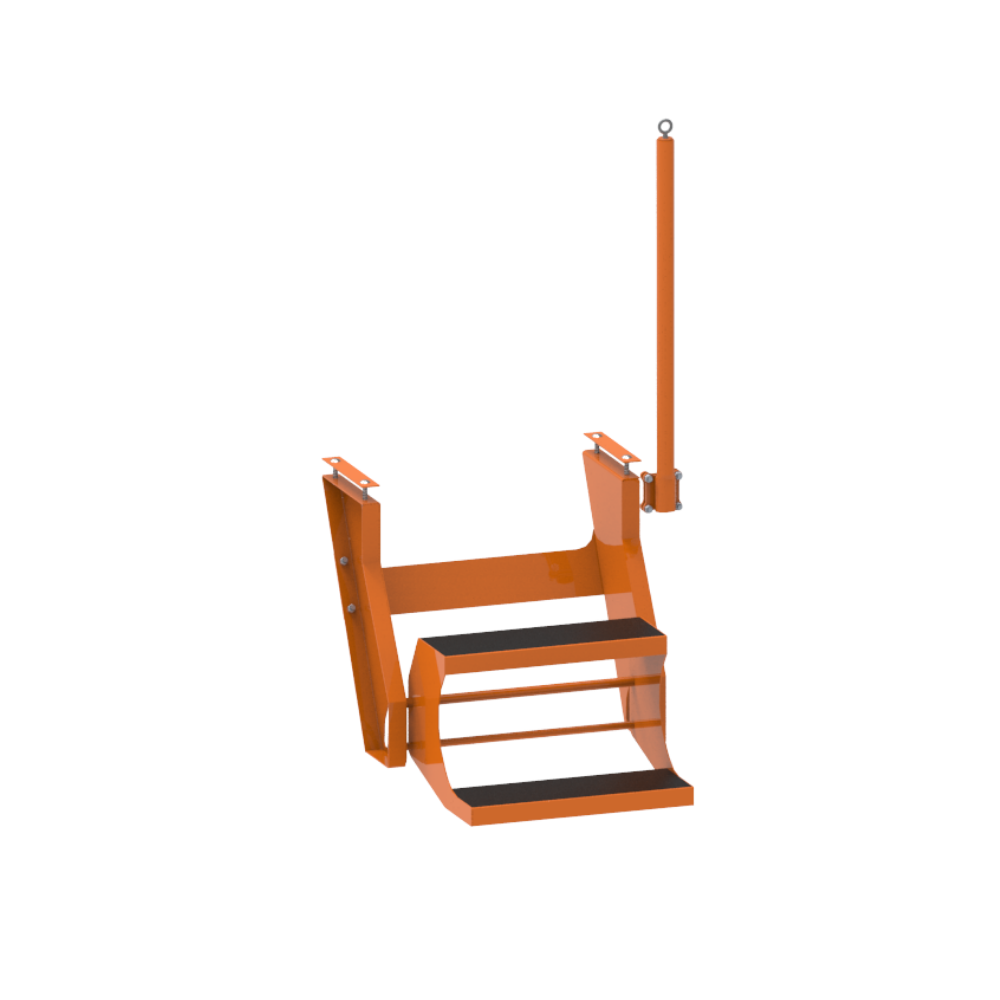

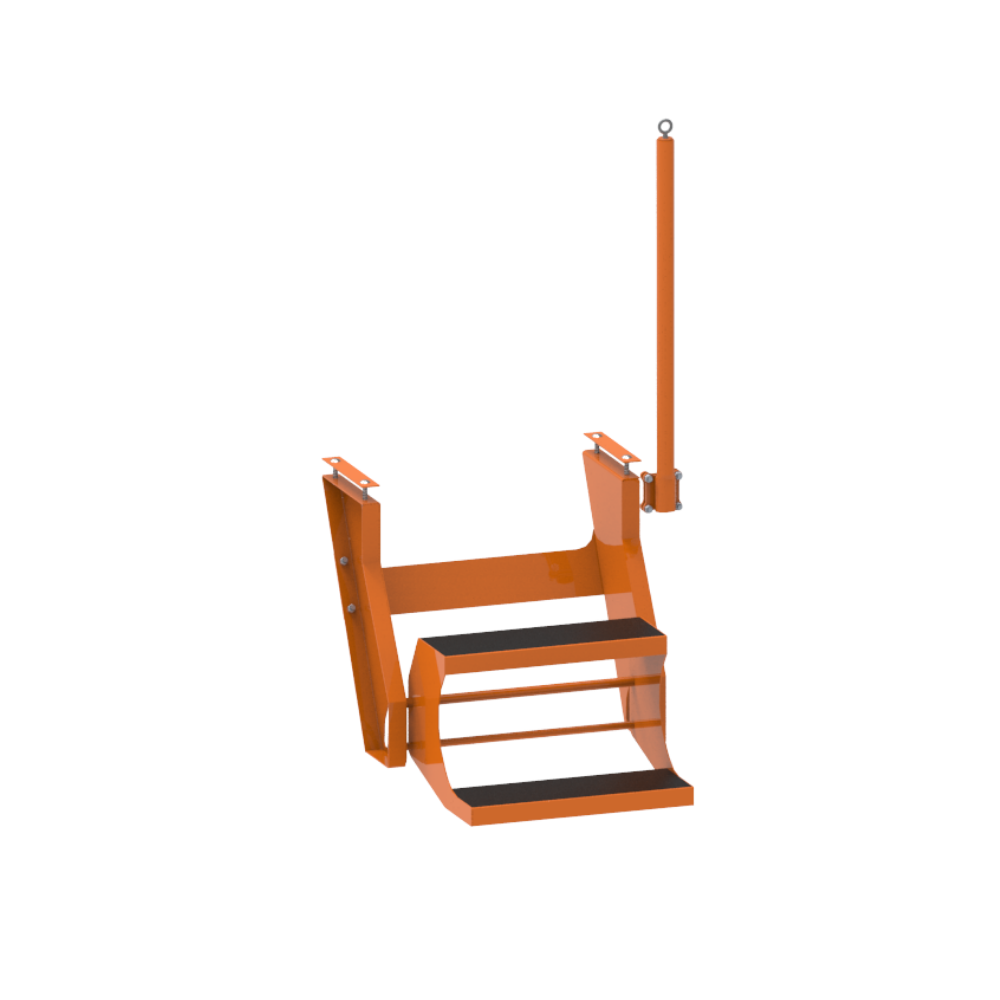

trailer step kit

Mounts under a step deck and makes getting on and off the deck safe and easy. Includes a grab handle.

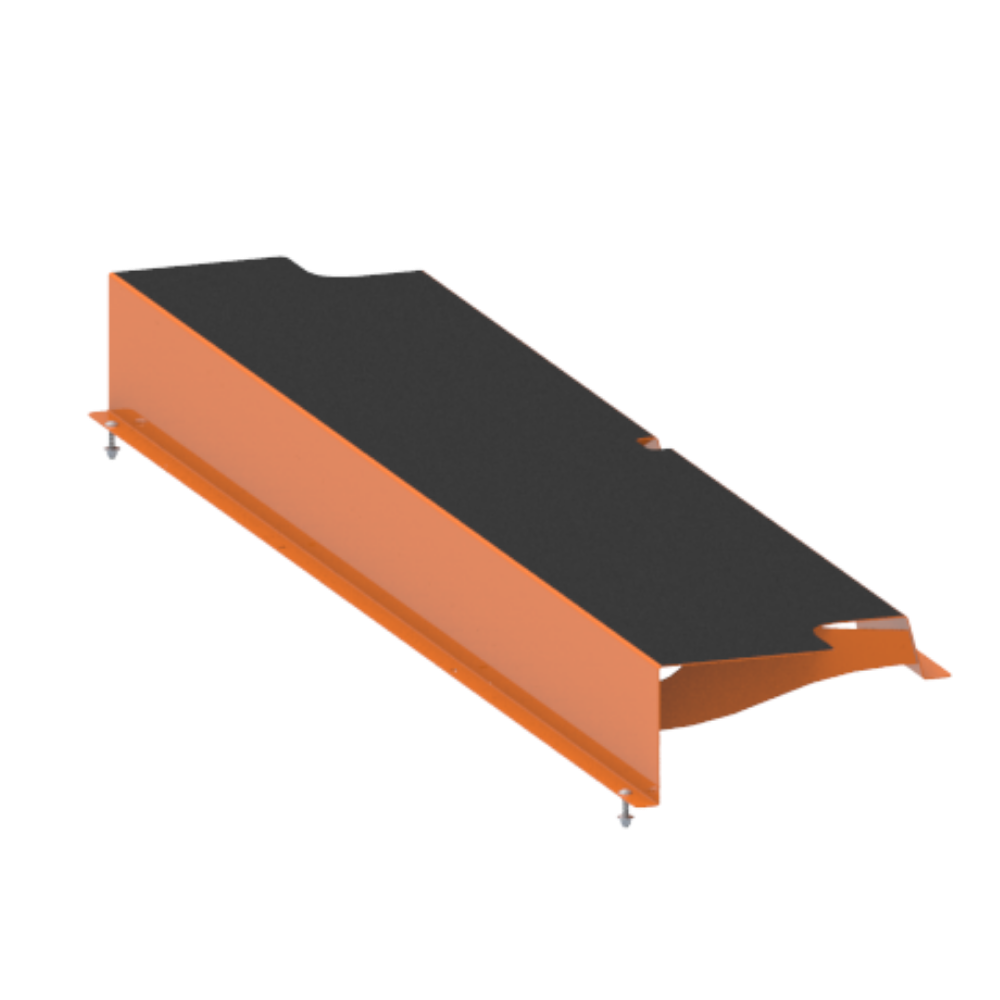

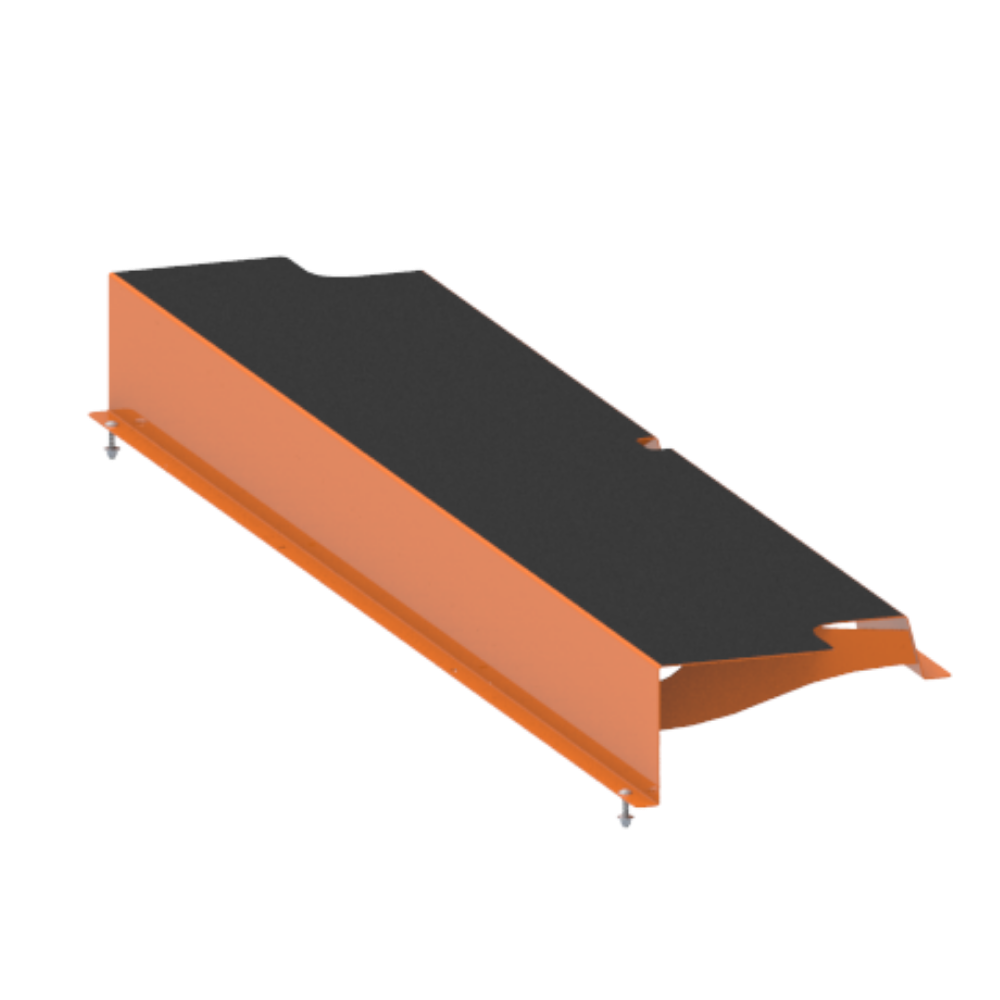

working platform

Designed to mount to the Dash 4.0 to improve ergonomic comfort while loading jugs.

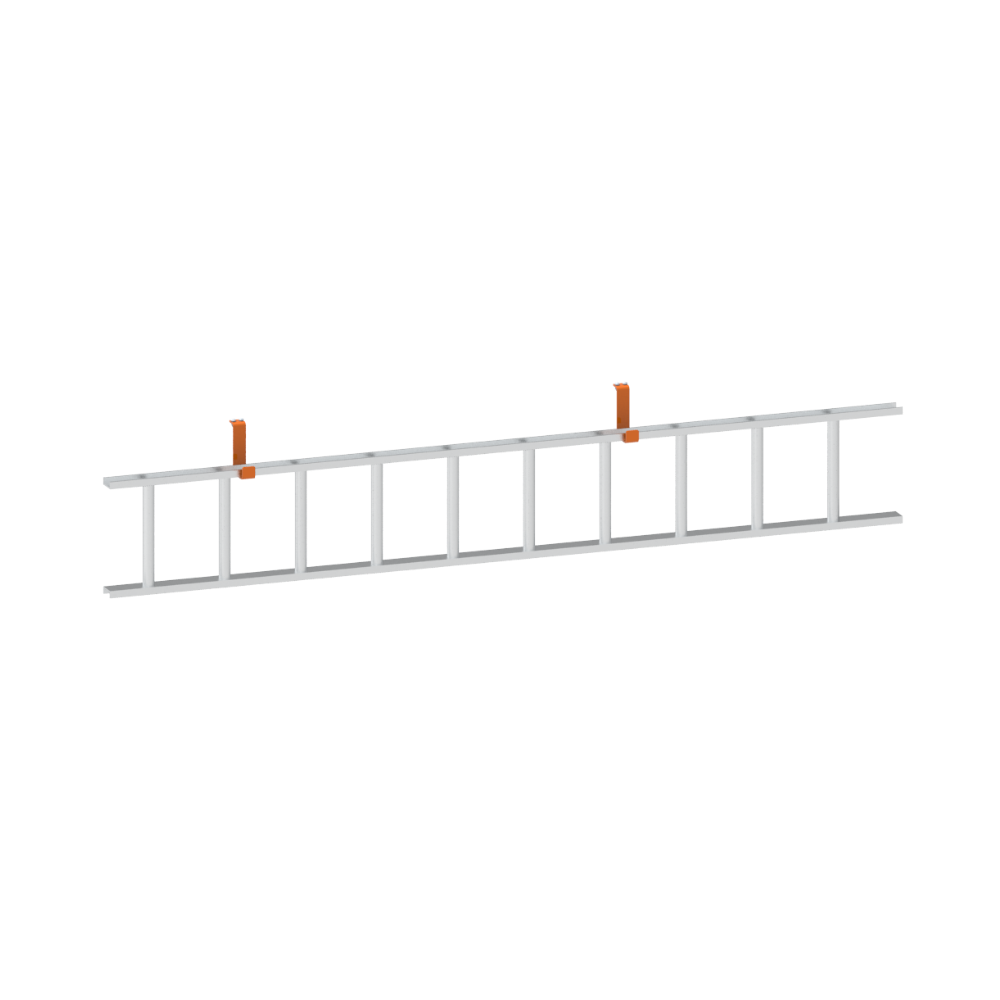

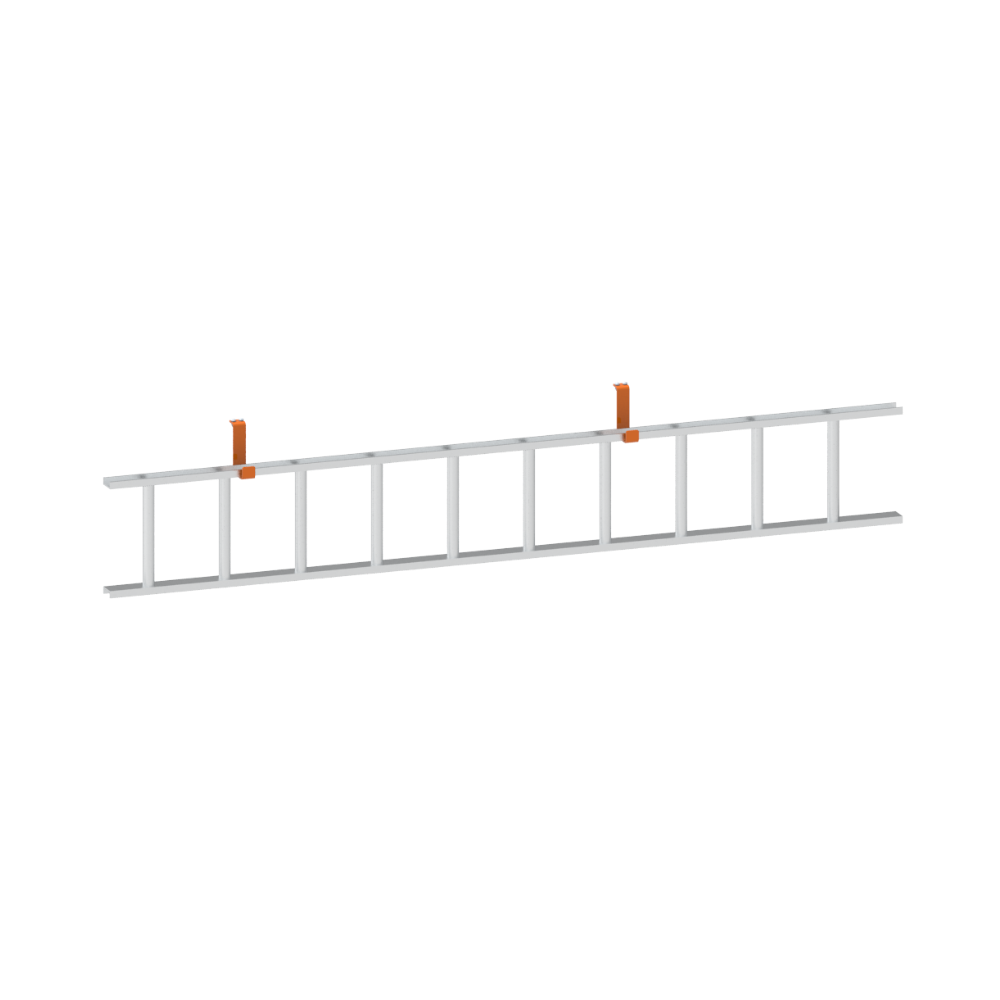

ladder kit

4 wheel ramp kit

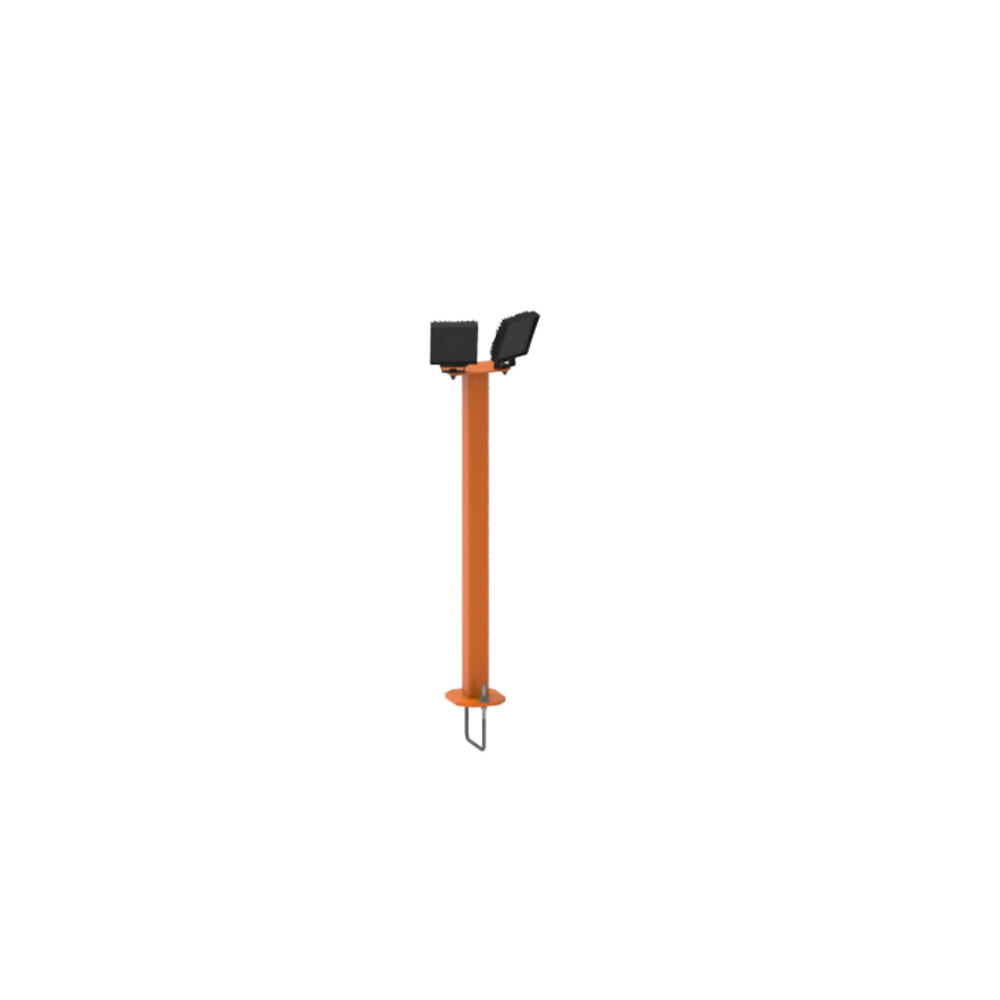

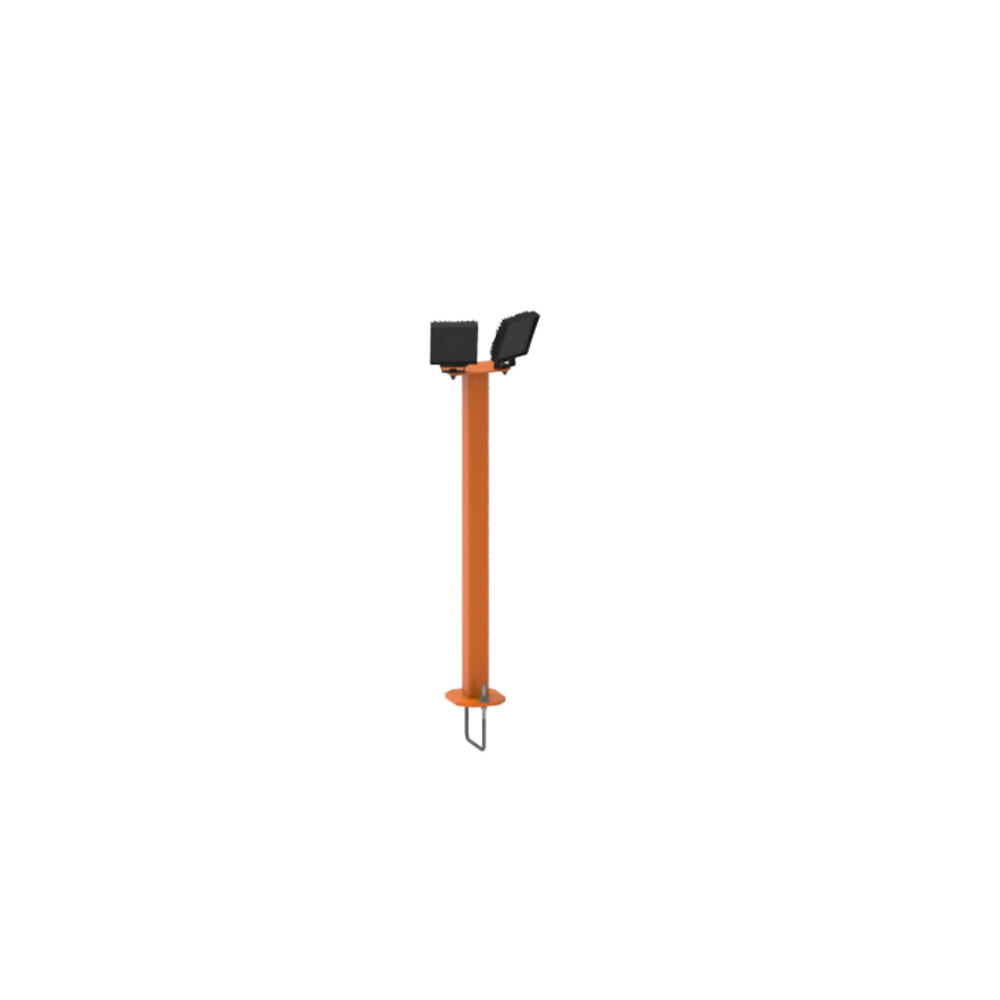

Unit Light kit

Never work in the dark again. Includes mounting post and two LED flood lights.

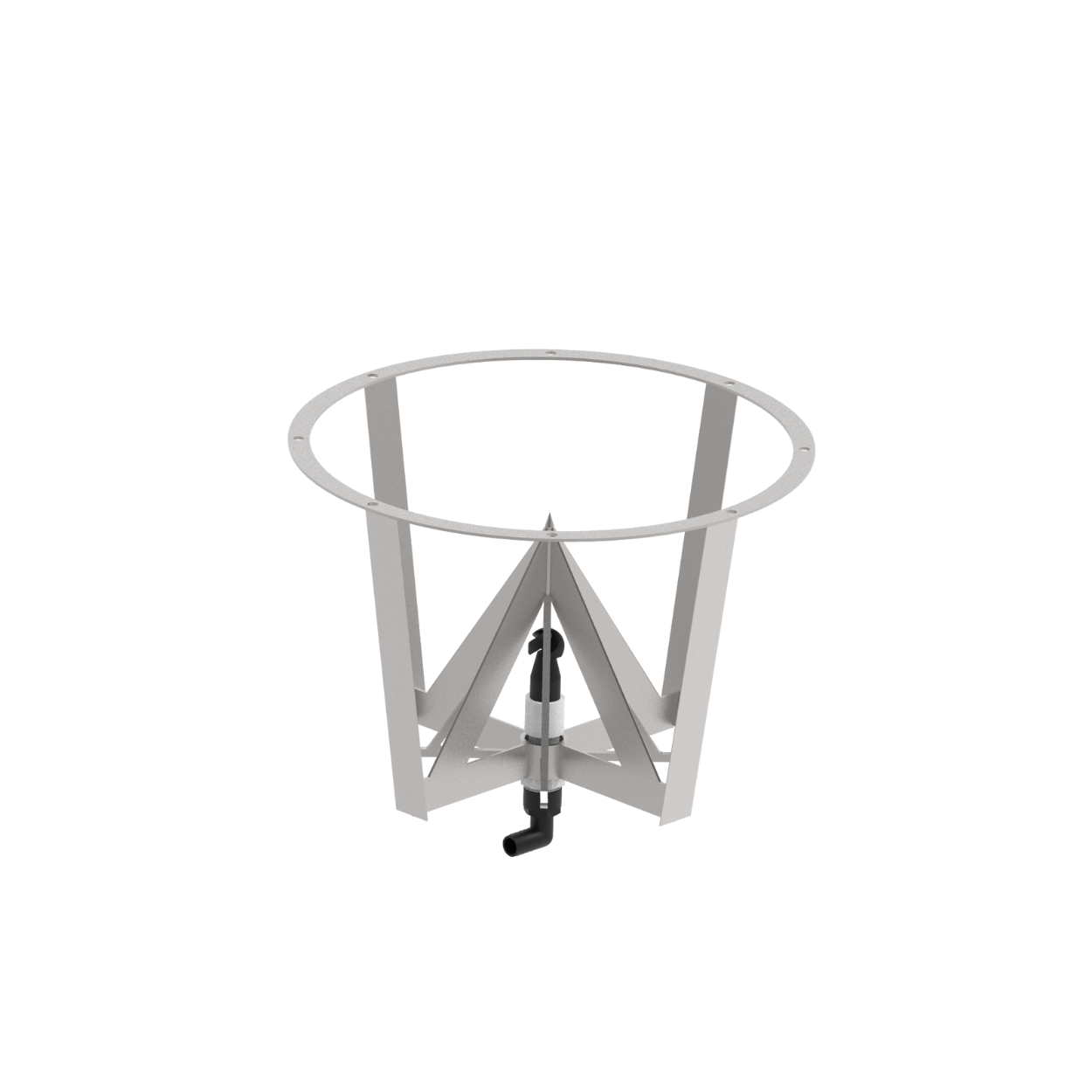

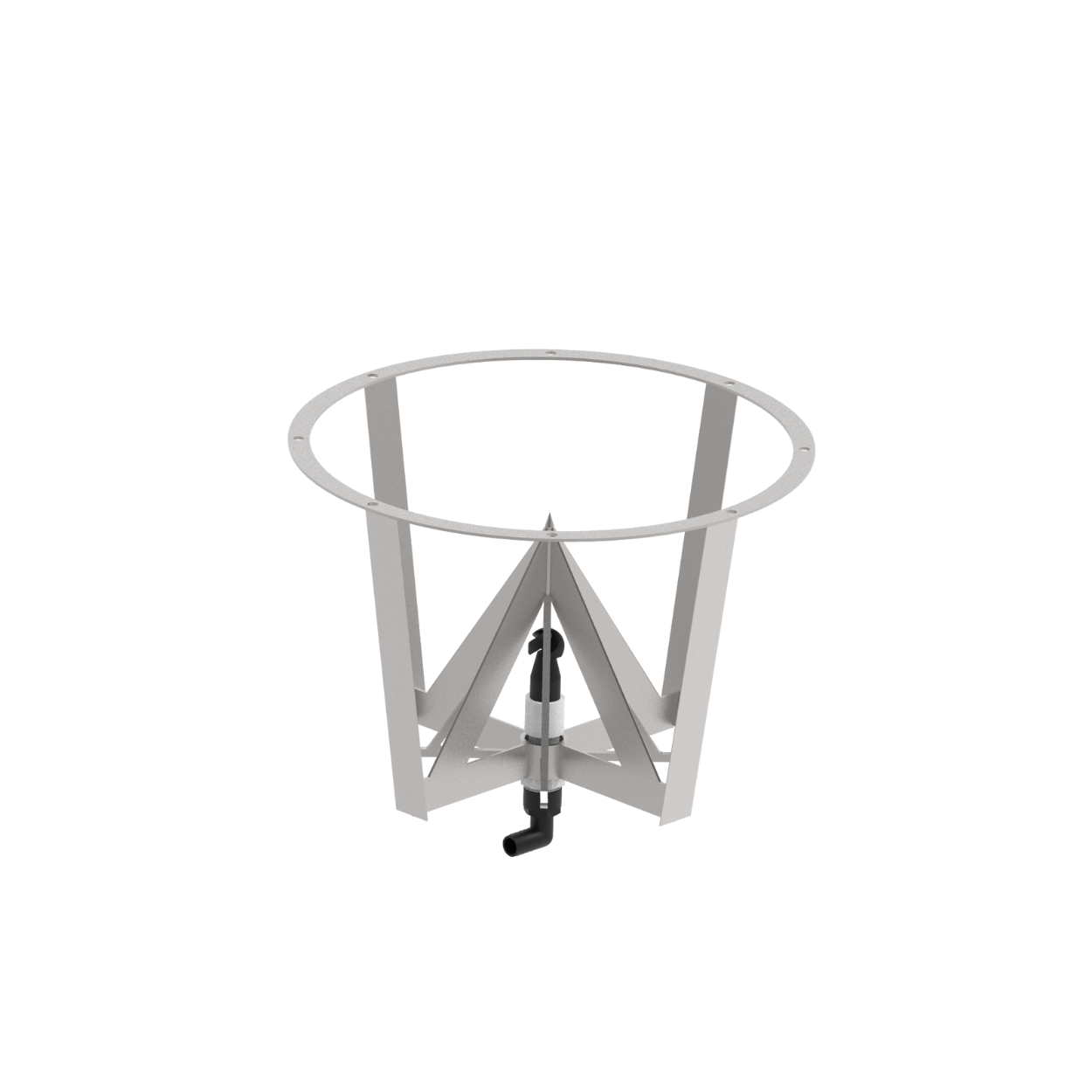

dry agitatOr kit

Powered by air and designed to mix heavy rates of dry products into water.

Jug knife kit

Replace the standard inductor/jug rinse with a jug knife. Includes a patent tank/jug wash nozzle like standard inductors. Can be fitted in all four inductors.

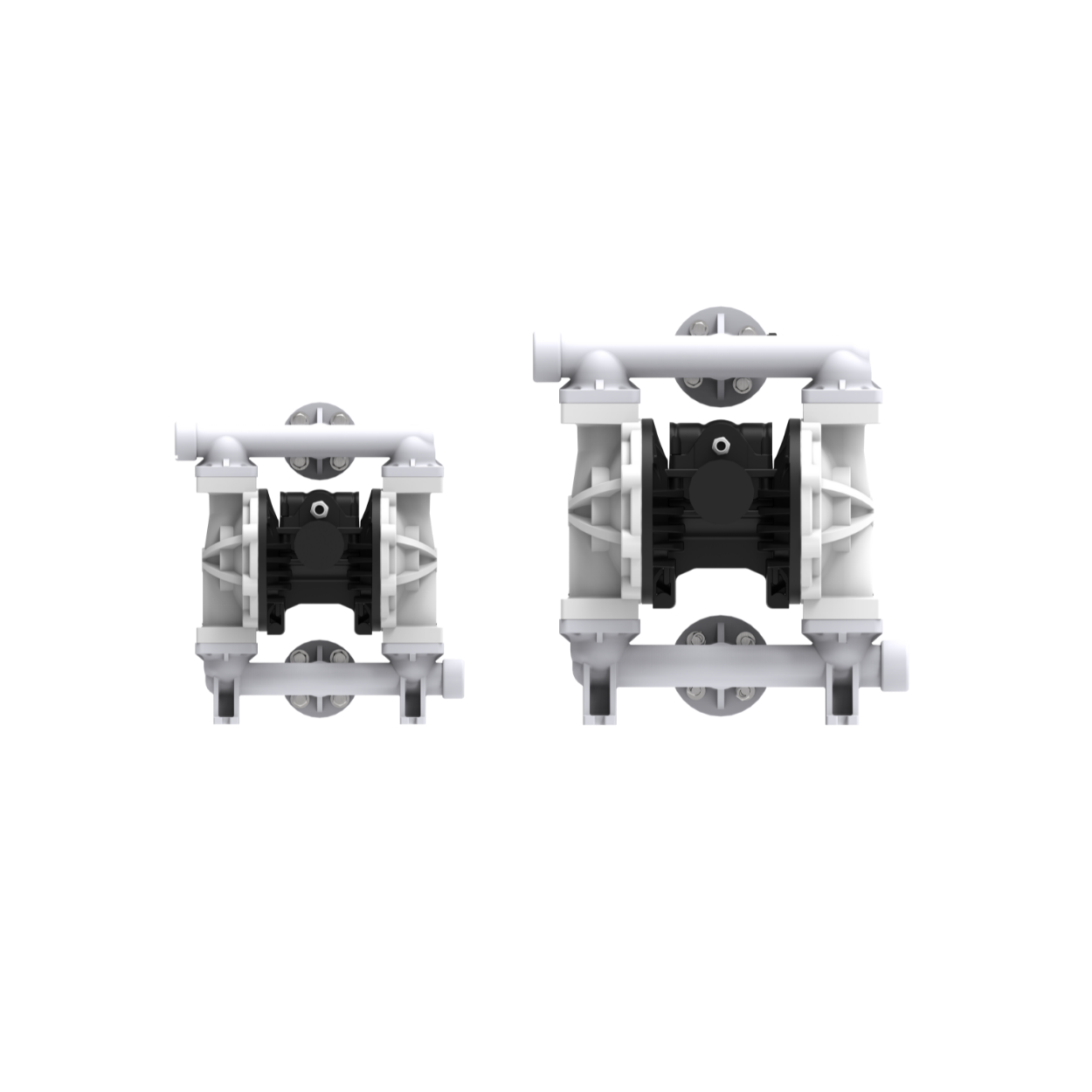

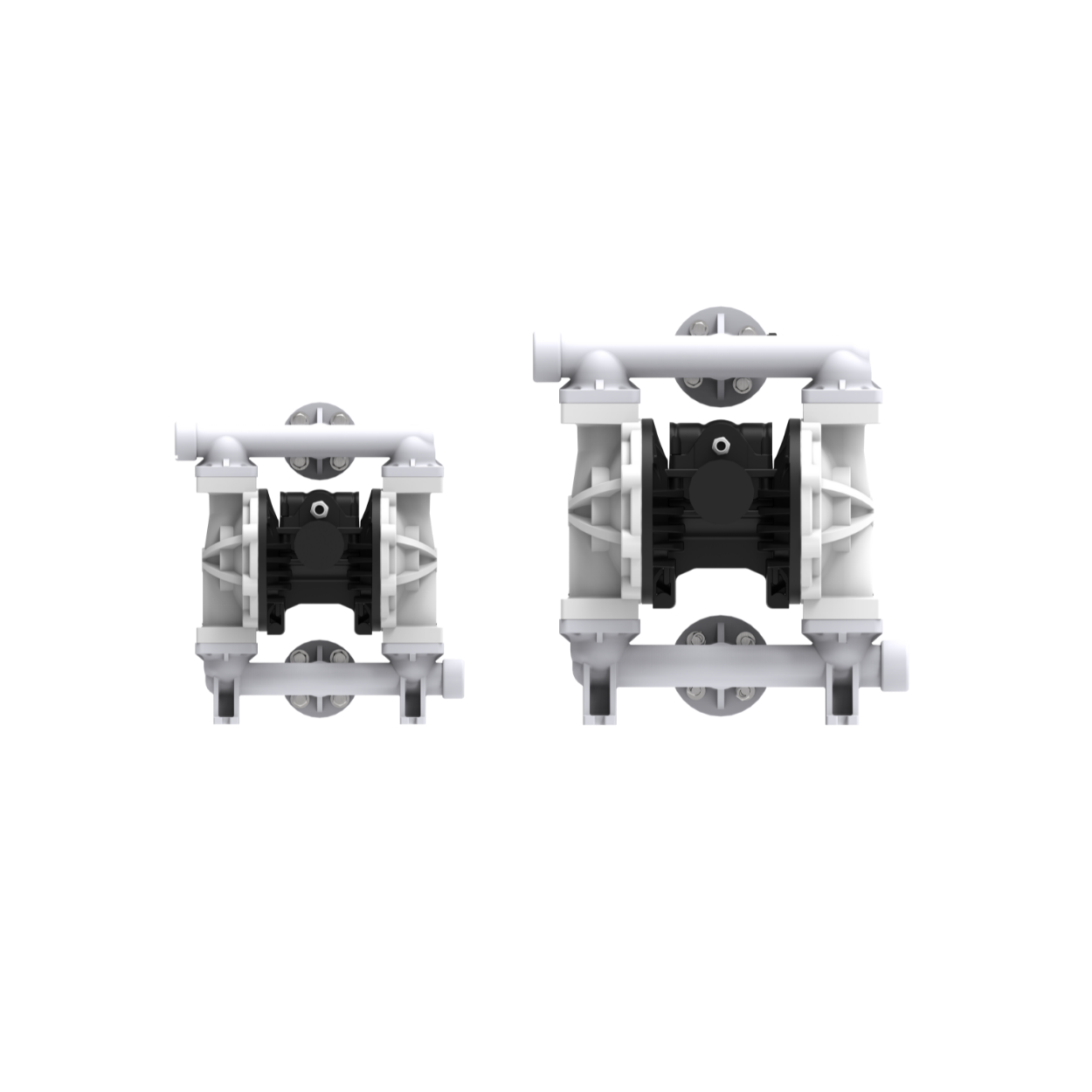

chemical transfer pump

Choose between a 20 GMP or 40 GMP air powered diaphragm pump is the heart of the rinse and agitate system. This pump is used for rinsing jugs, inductors and getting dry chemicals into suspension. It also controls the hand sprayer and wash down for a complete and easy clean out.

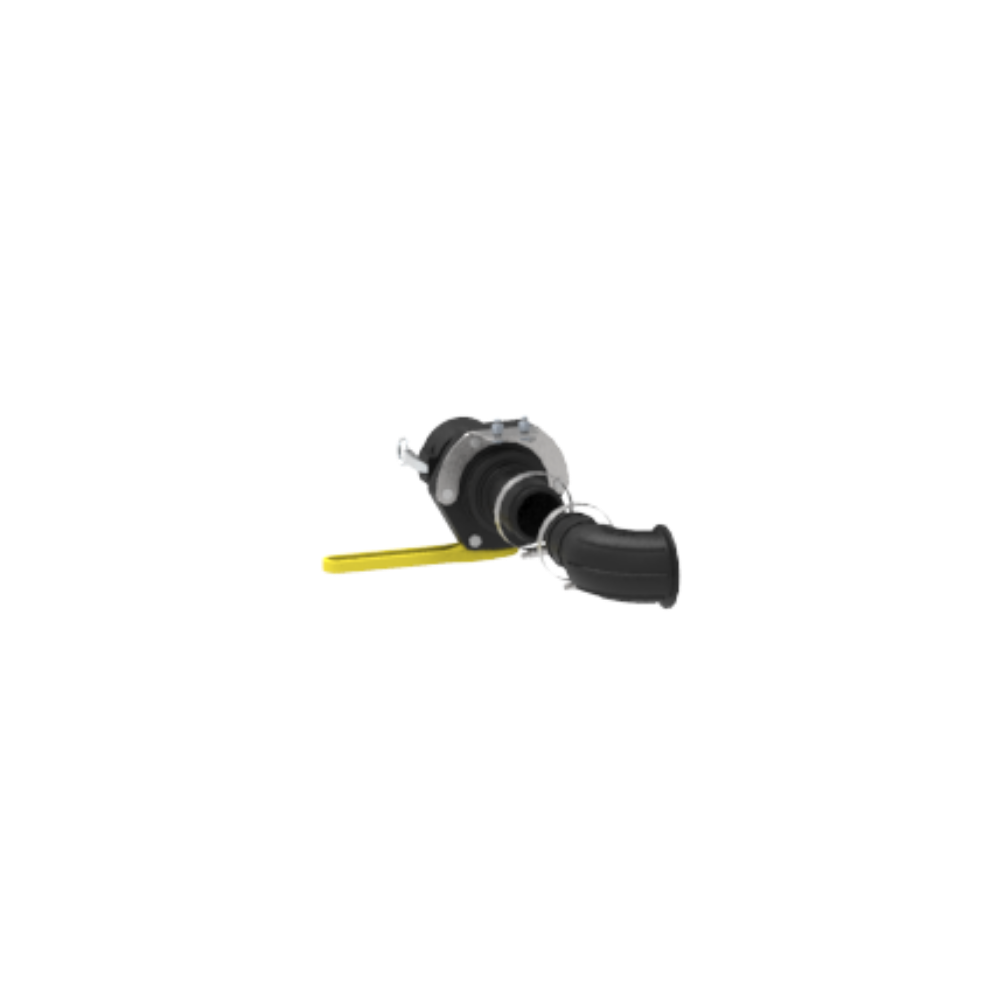

Rear or side refil

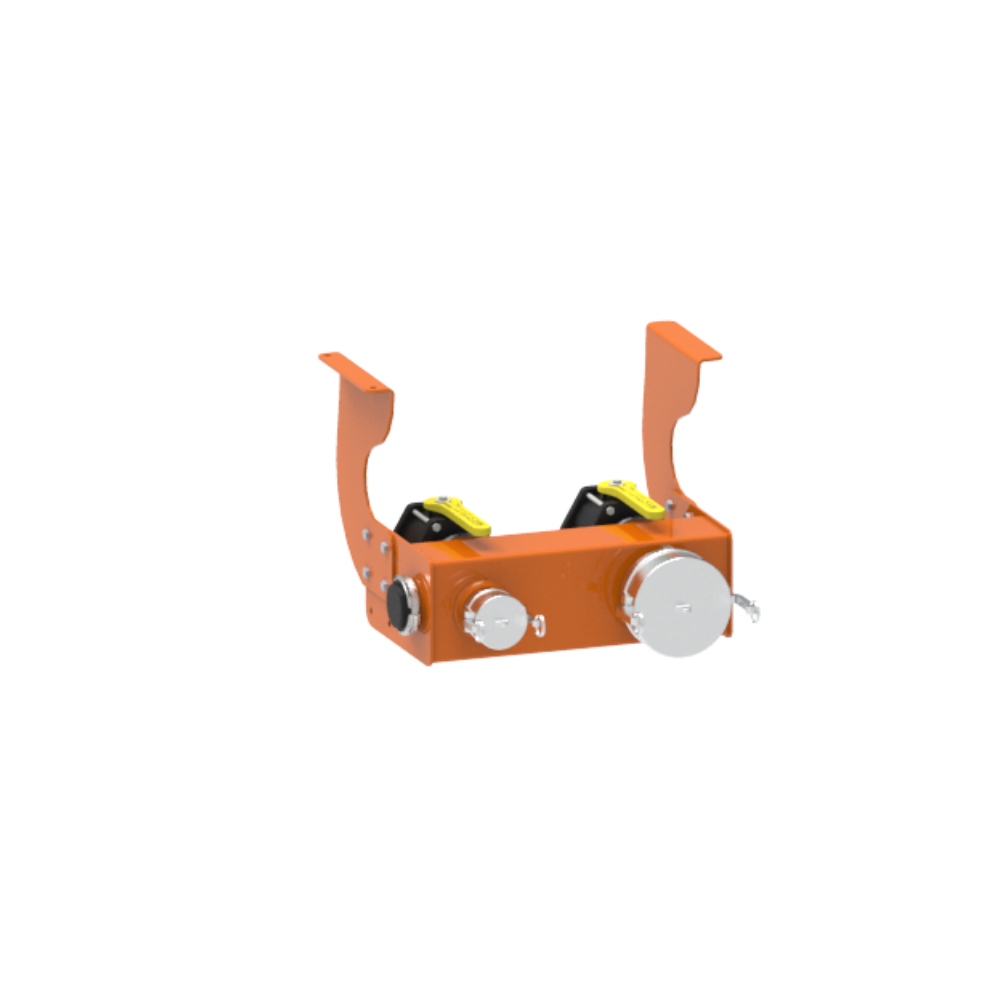

Manifold

Manage up to 3 tanks with a central fill/draw point. 3” ports configured for high flow. Fill with 3” or 6” ports, with a 4″ port option available.

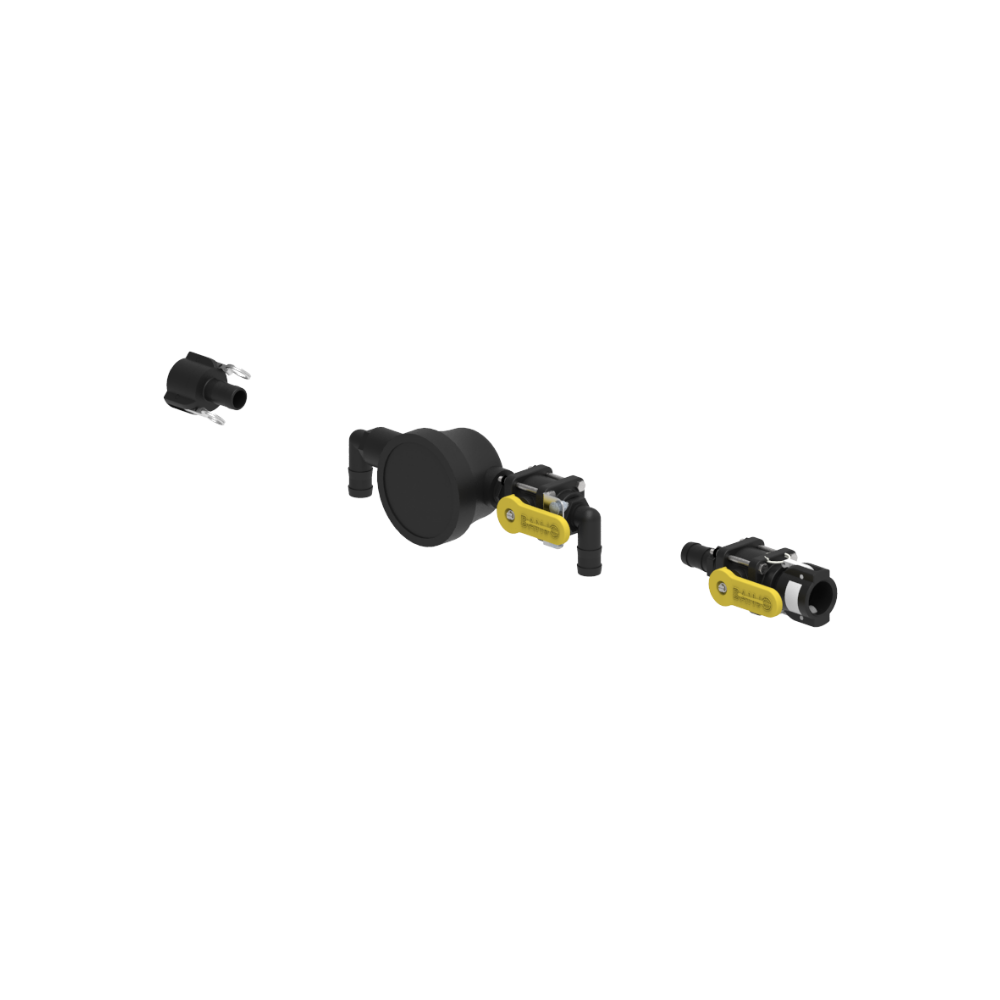

deck bulkhead

No more tripping over hoses. Transition 3” hoses from above deck to below deck without restricting flow. Easy to orient hoses.

boom blowout

auxiliary chemical meter

Meter directly from barrels to totes .5′ or 6′ high configurations.

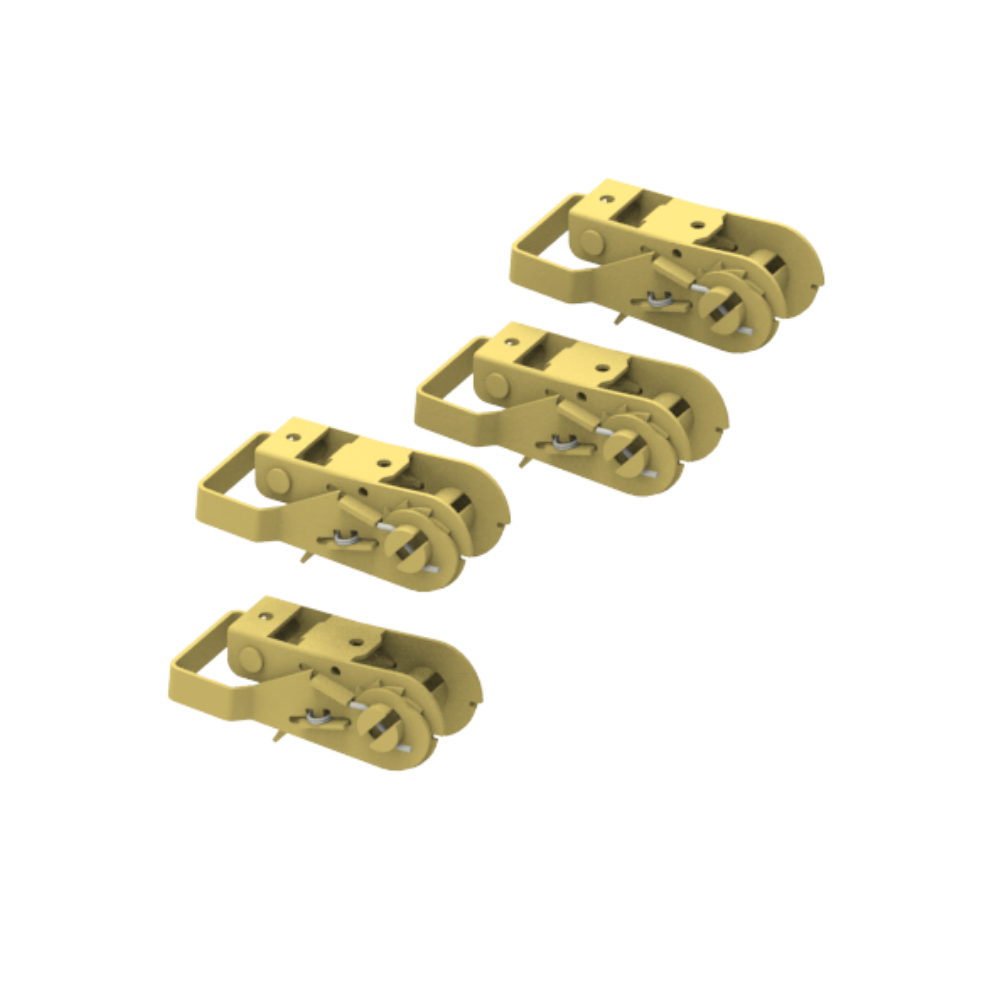

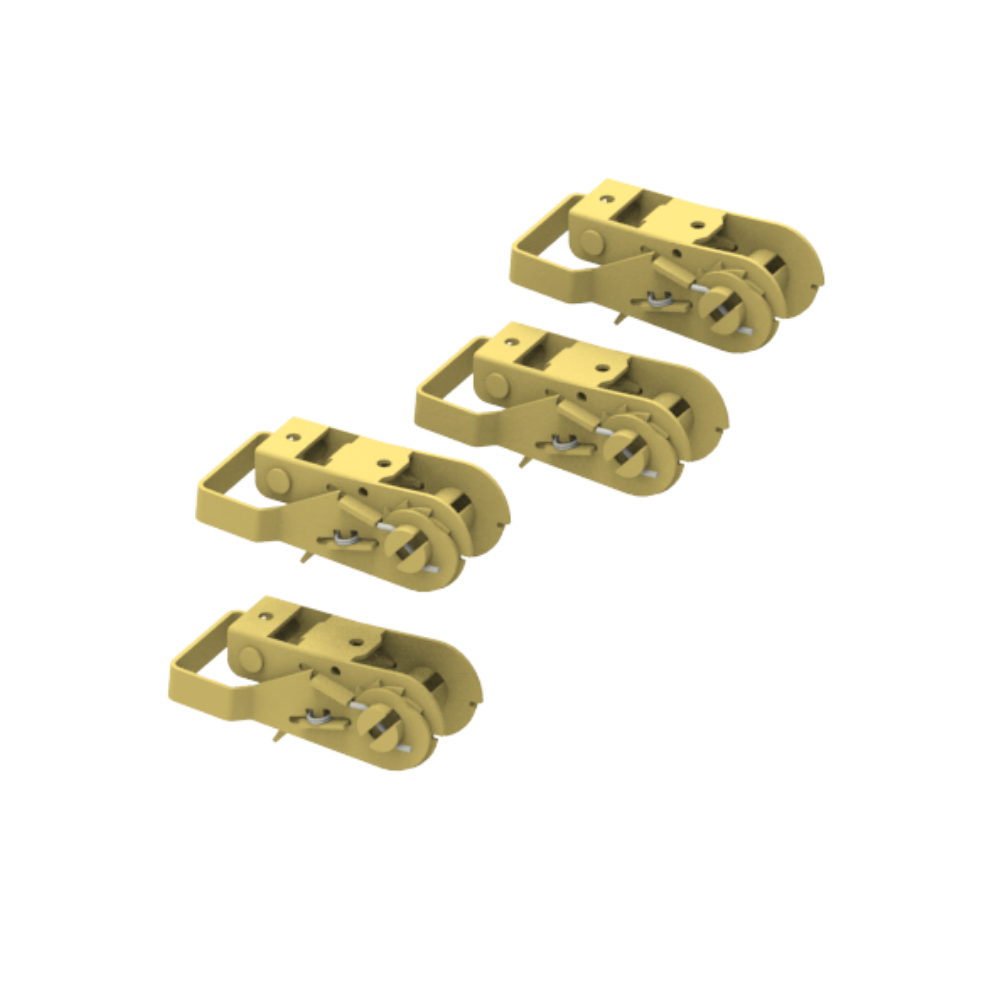

ratchet straps

Trailer Lighting kit

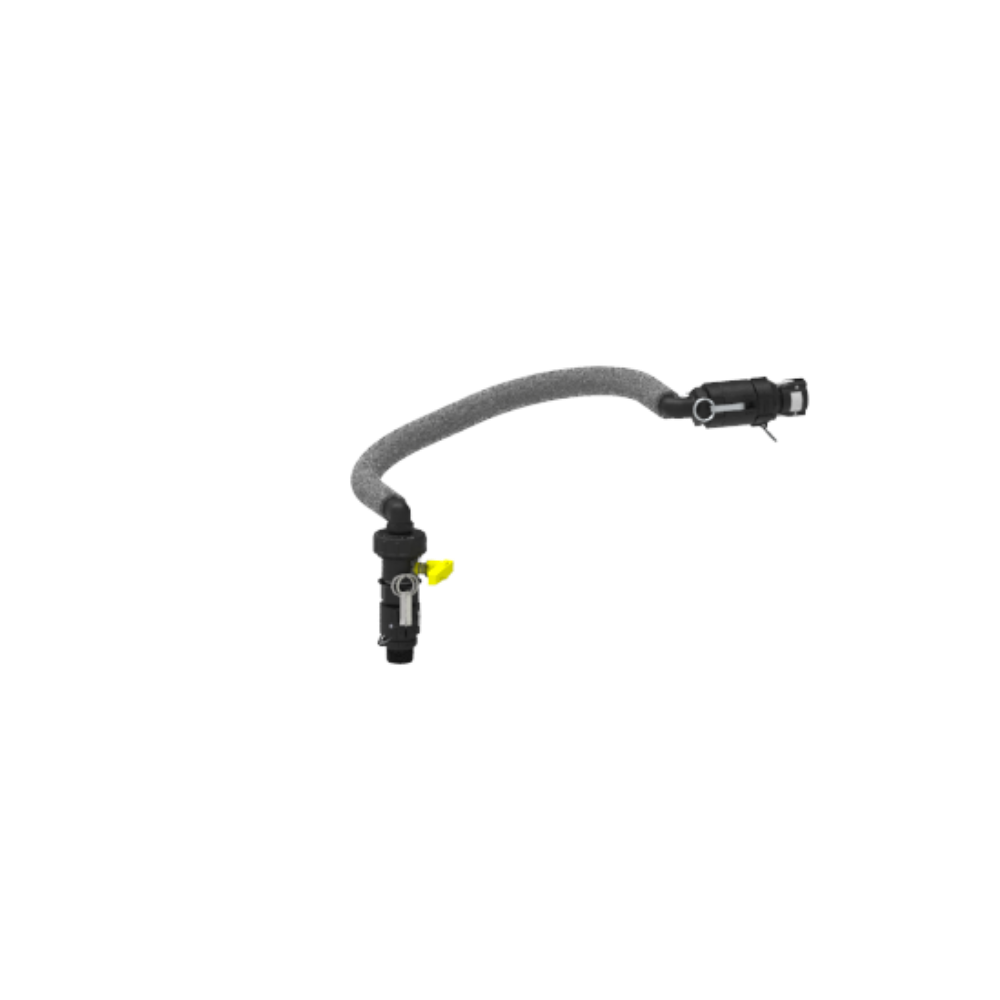

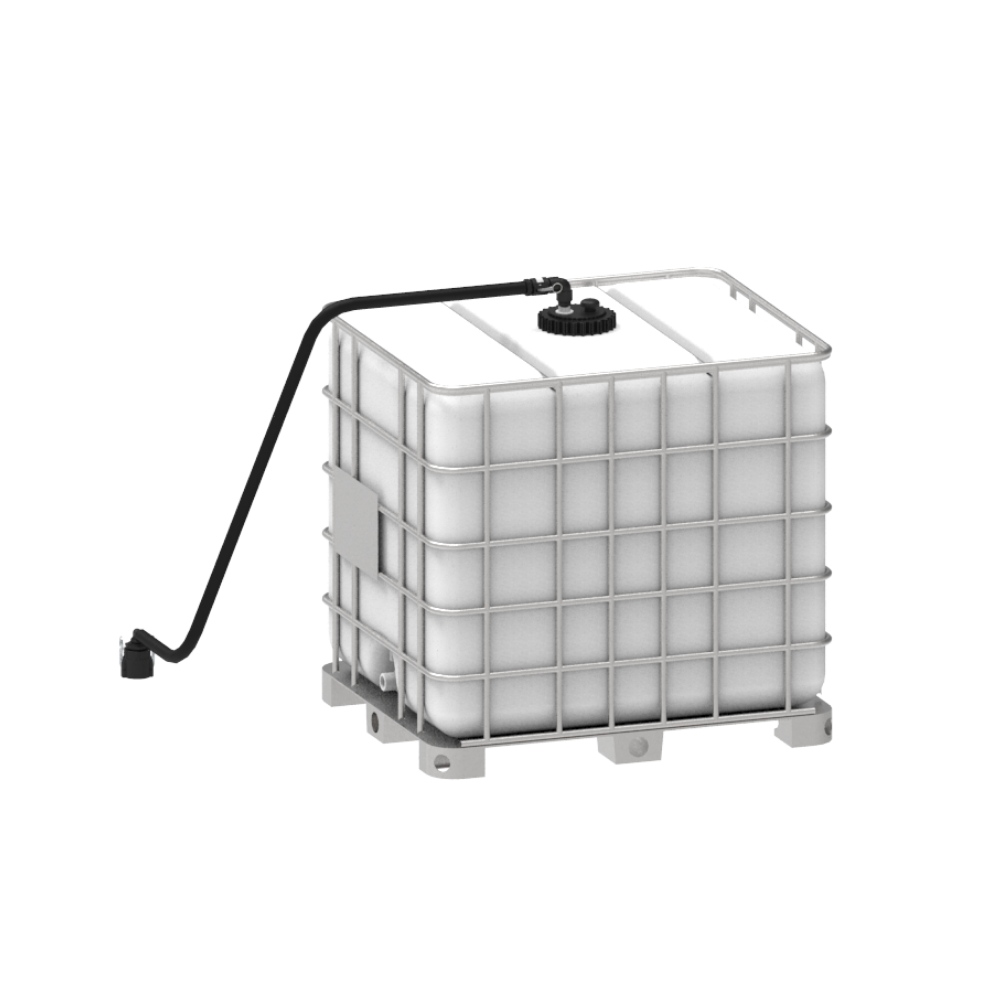

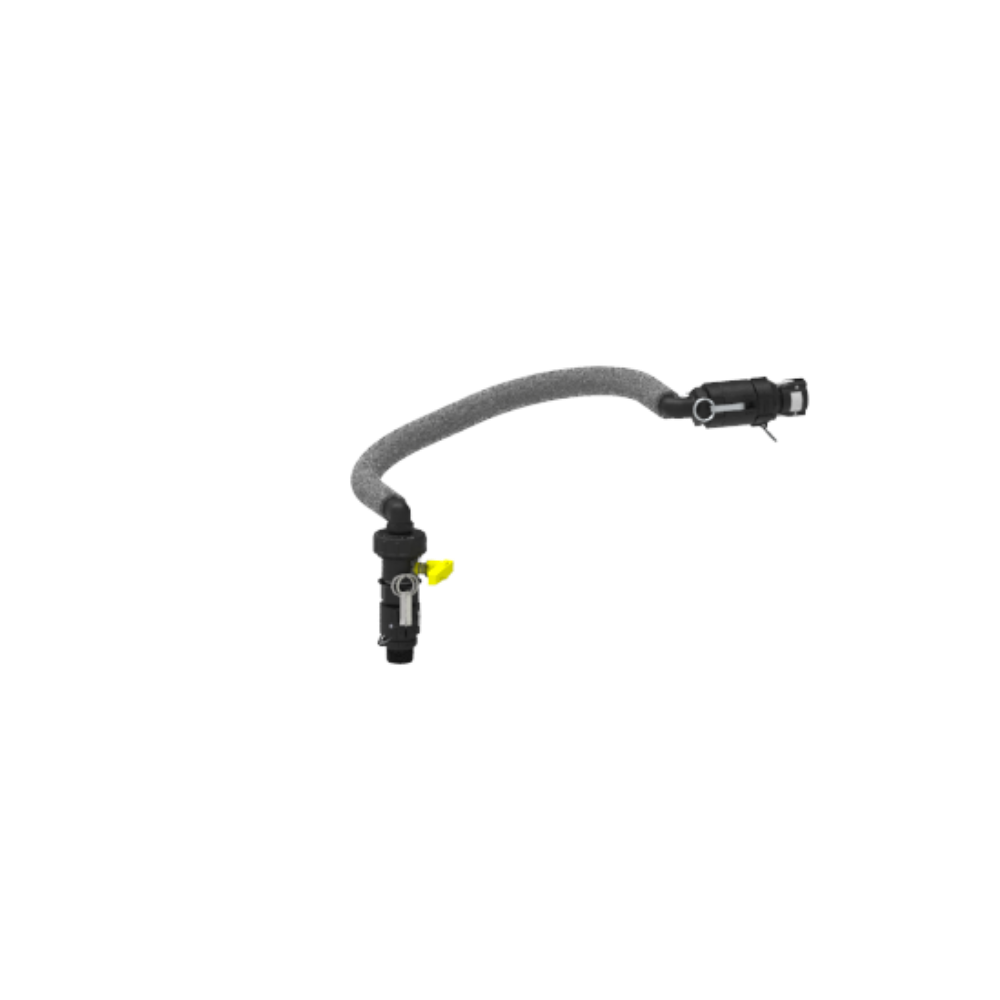

tote hose

Available Options

Tanks

Includes hoops for mounting and internal baffles.

| Capacity | W” x L” x H” |

| 3,250 gal | 88 x 146 x 79 |

| 3,750 gal | 88 x 146 x 91 |

| 4,250 gal | 88 x 146 x 101 |

Cage with tote platform

Keep pallets of boxes contained while transporting. Load from either end or access from side door. Store totes above on tote platform. Available in 5’ or 6’ high configurations.

tote platform

IDesigned to mount to the Dash to store totes above inductor tanks and use gravity to fill. No transfer pumps needed, gravity always works on earth. Frees up deck space..

cargo net

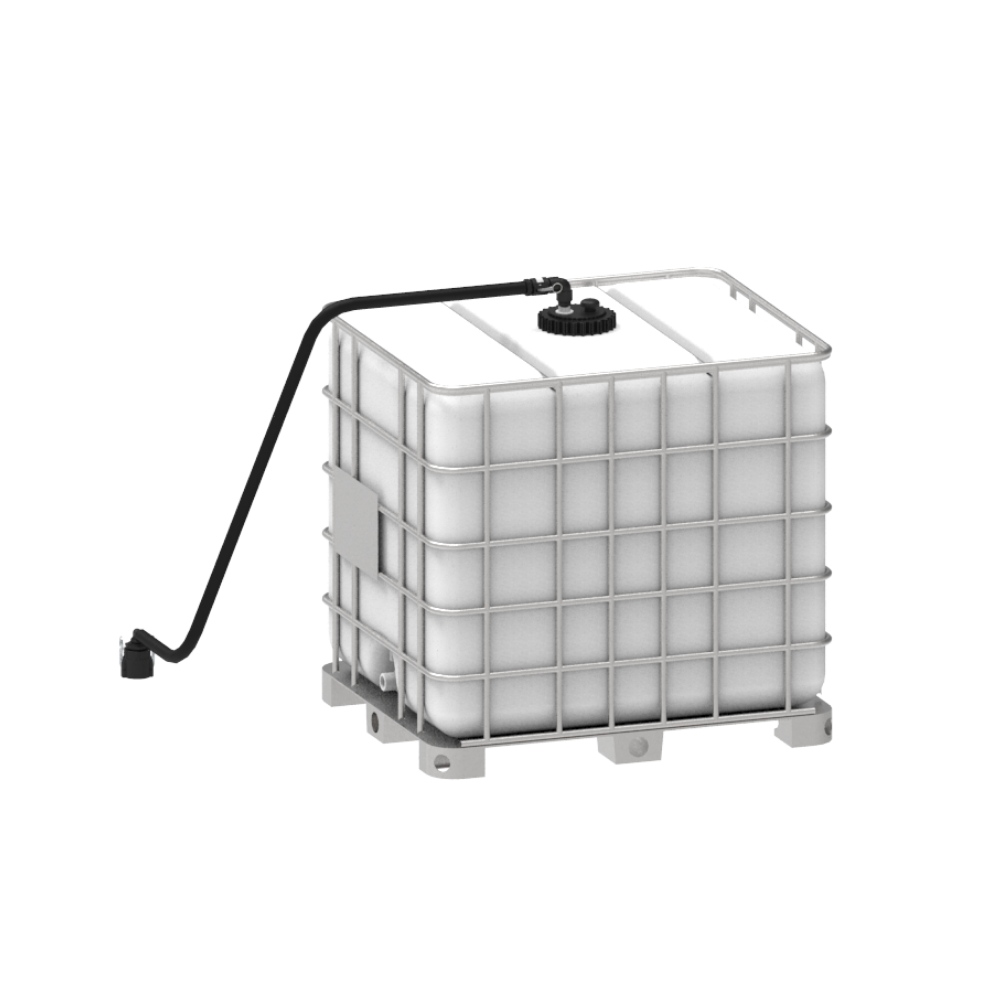

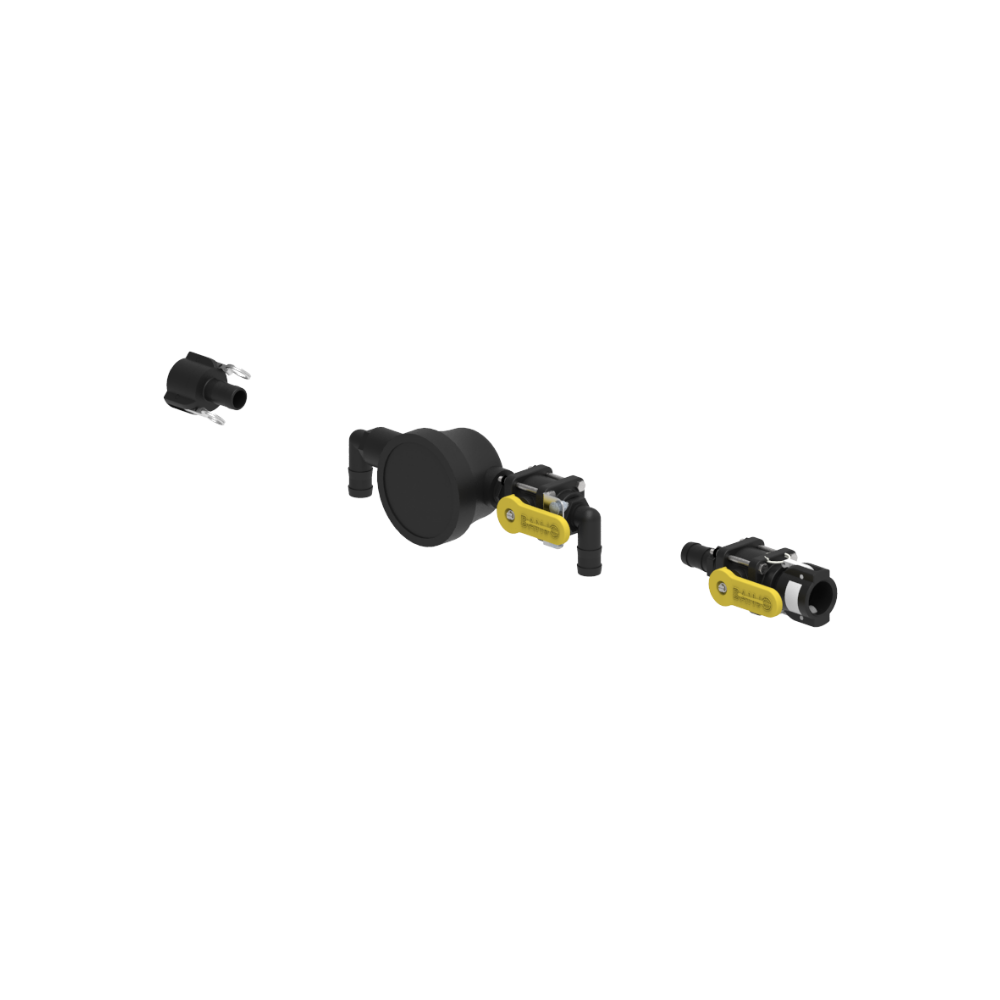

tote rinse kit

60 gal air stronage kit

An additional air tank can be added. This tank has a valve that allows the truck to air up first, before storing an additional 60 gallons of air.

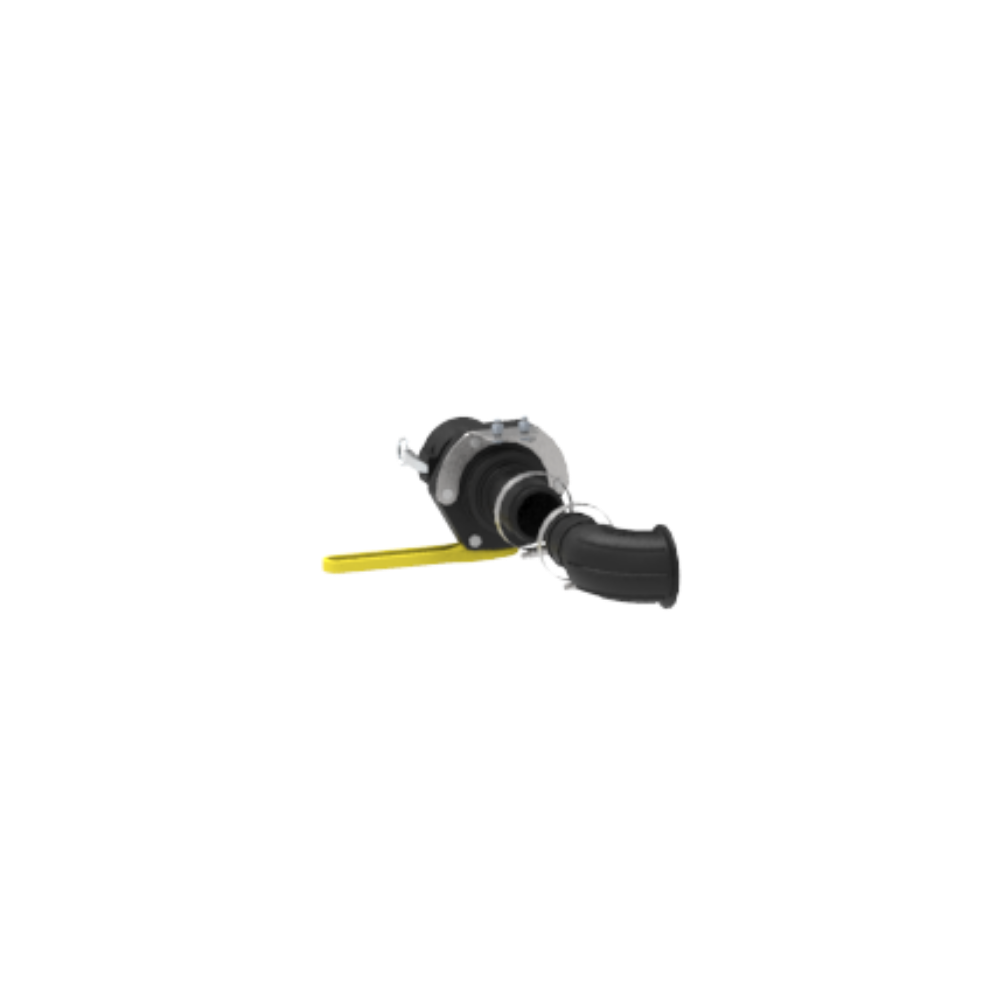

boom kit

INo more lugging heavy hose. Mounts to Dash and has approximately 28’ of total extension. Includes boom cradle and quick release handle. Premium Hose Kit available.

trailer step kit

Mounts under a step deck and makes getting on and off the deck safe and easy. Includes a grab handle.

working platform

Designed to mount to the Dash 4.0 to improve ergonomic comfort while loading jugs.

ladder kit

4 wheel ramp kit

Unit Light kit

Never work in the dark again. Includes mounting post and two LED flood lights.

dry agitatr kit

Powered by air and designed to mix heavy rates of dry products into water.

Jug knife kit

Replace the standard inductor/jug rinse with a jug knife. Includes a patent tank/jug wash nozzle like standard inductors. Can be fitted in all four inductors.

chemical transfer pump

Choose between a 20 GMP or 40 GMP air powered diaphragm pump is the heart of the rinse and agitate system. This pump is used for rinsing jugs, inductors and getting dry chemicals into suspension. It also controls the hand sprayer and wash down for a complete and easy clean out.

Rear or side refil

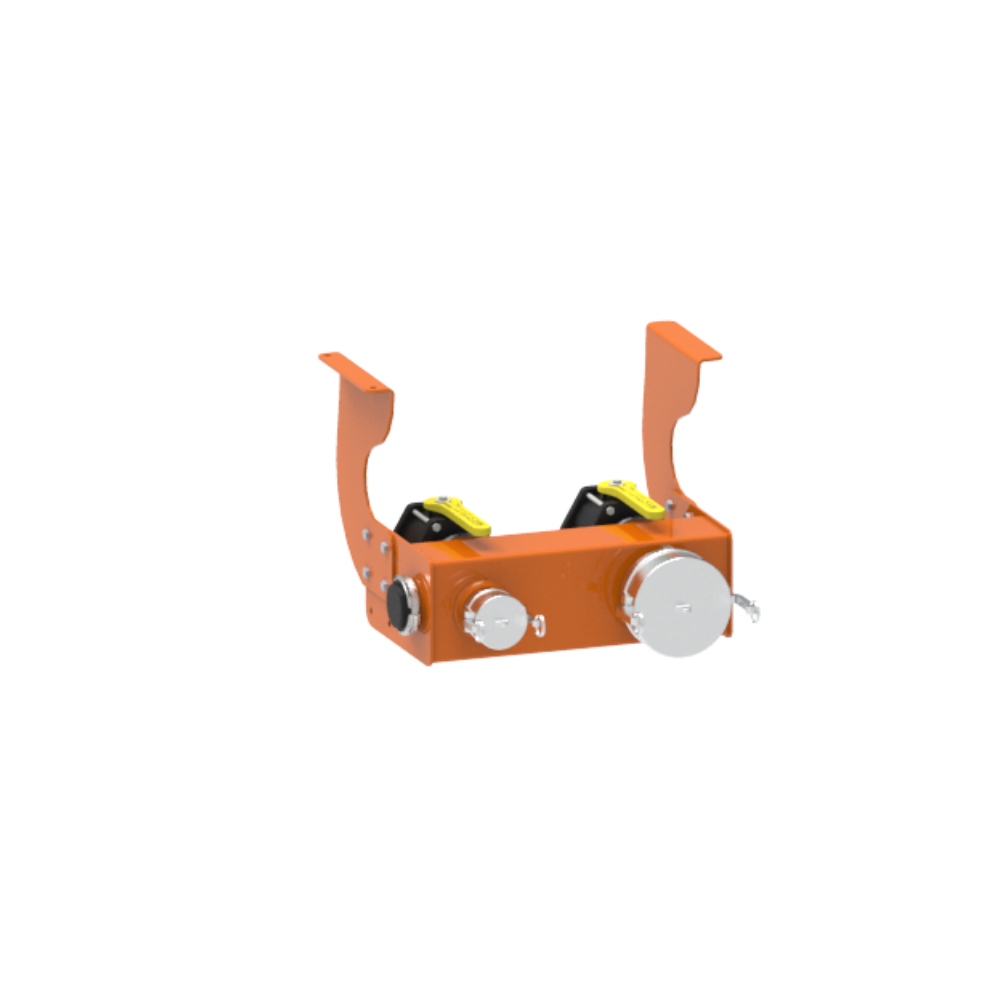

Manifold

Manage up to 3 tanks with a central fill/draw point. 3” ports configured for high flow. Fill with 3” or 6” ports, with a 4″ port option available.

deck bulkhead

No more tripping over hoses. Transition 3” hoses from above deck to below deck without restricting flow. Easy to orient hoses.

boom blowout

auxiliary chemical meter

Meter directly from barrels to totes .5′ or 6′ high configurations.

ratchet straps

Trailer Lighting kit

tote hose

Advantages

Speed of Loading

chemical seperation

ease of use

The Dash makes loading different chemicals a simple, safe, and seamless process. After loading each chemical into its designated inductor, connect to the sprayer, stand at the side of the trailer, and operate the control levers from one location.

cleaning

During operation, each inductor is rinsed with fresh water using a patented rinse nozzle as it unloads, alleviating chemical build up on inductor walls.

A more extensive, yet still simple, cleaning process is required when changing chemicals. Fill one inductor with the cleaning agent, the rinse pump source is changed to the inductor containing the cleaning agent and then all four inductors are rinsed out. The Dash has a hand-held spray gun which can be used for any type of internal or external cleaning or rinsing.

From the Field

Customer Testimonials

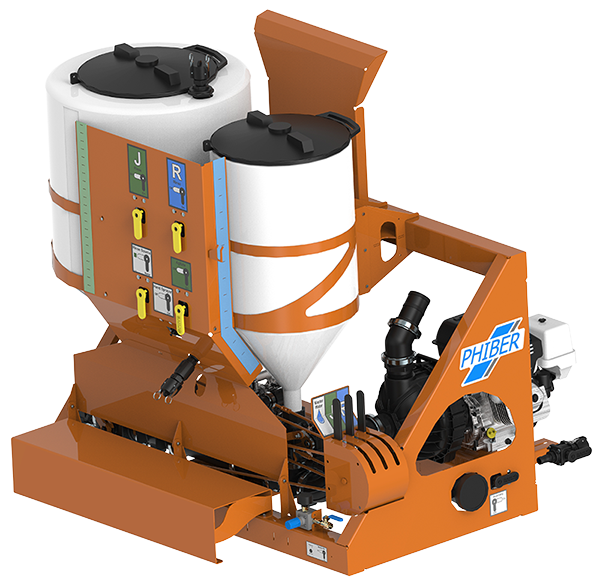

DASH Models

Hover and Click for Interactive Display and Video

2.0 dash

CENTER MOUNT

This configuration of the Dash is designed to mount on a flat deck trailer. It has a 95 Gal total storage with 1 65 Gal jug and 1 30 Gal jug. It comes with two pumps, an air diaphragm pump for auto rinsing features and high delivery water pump powered by a 13hp Honda with electric start. See below for accessories.

4.0 dash

CENTER MOUNT

This configuration of the Dash is designed to mount on a flat deck trailer. It has a 190 Gal total storage with 2 x 65 Gal jugs and 2 x 30 Gal jugs. It comes with two pumps, an air diaphragm pump for auto rinsing features and high delivery water pump powered by a 13hp Honda with electric start. See below for accessories.

4.0 dash

REAR MOUNT

This configuration of the Dash is designed to mount on the back of a tanker, flat deck trailer or grain box. It has all the same features of the center mount Dash but with a different frame to support a different mounting. This model includes tail/turn lights, flip down work platform and a license plate holder. See below for accessories.

Downloads

Home Office (Canada)

PhiBer Manufacturing Inc.

P.O. Box 58, 108 New Hope Dr.

Crystal City, MB R0K 0N0

Office (US)

PhiBer Manufacturing Inc.

P.O. Box 54, 68 Main Street

Sarles, ND 58372